The Smart Robot Revolutionizing Footwear Manufacturing

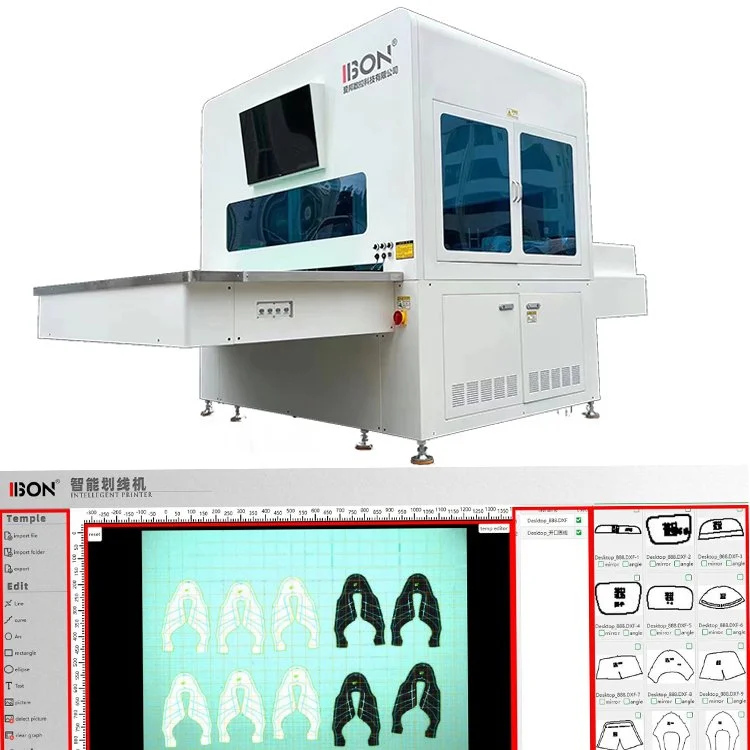

IBON Shoe Upper Marking Machine:

The footwear industry is accelerating its journey towards automation, and the shoe upper marking process—a critical step before sewing—is undergoing a transformative upgrade. IBON’s latest intelligent shoe upper marking machine is not just a piece of equipment; it’s the factory’s new “robot” that brings unprecedented precision, speed, and digital control to footwear production, leaving behind the era of manual and screen printing methods.

The “Robot” Role of the Shoe Upper Marking Machine in Modern Shoe Factories

In 2015, Adidas’s “Speedfactory” initiative exposed a significant automation gap in the footwear industry worldwide. This revelation sparked a wave of innovation, particularly targeting bottlenecks like upper marking, where traditional manual tracing and screen printing limit efficiency and quality.

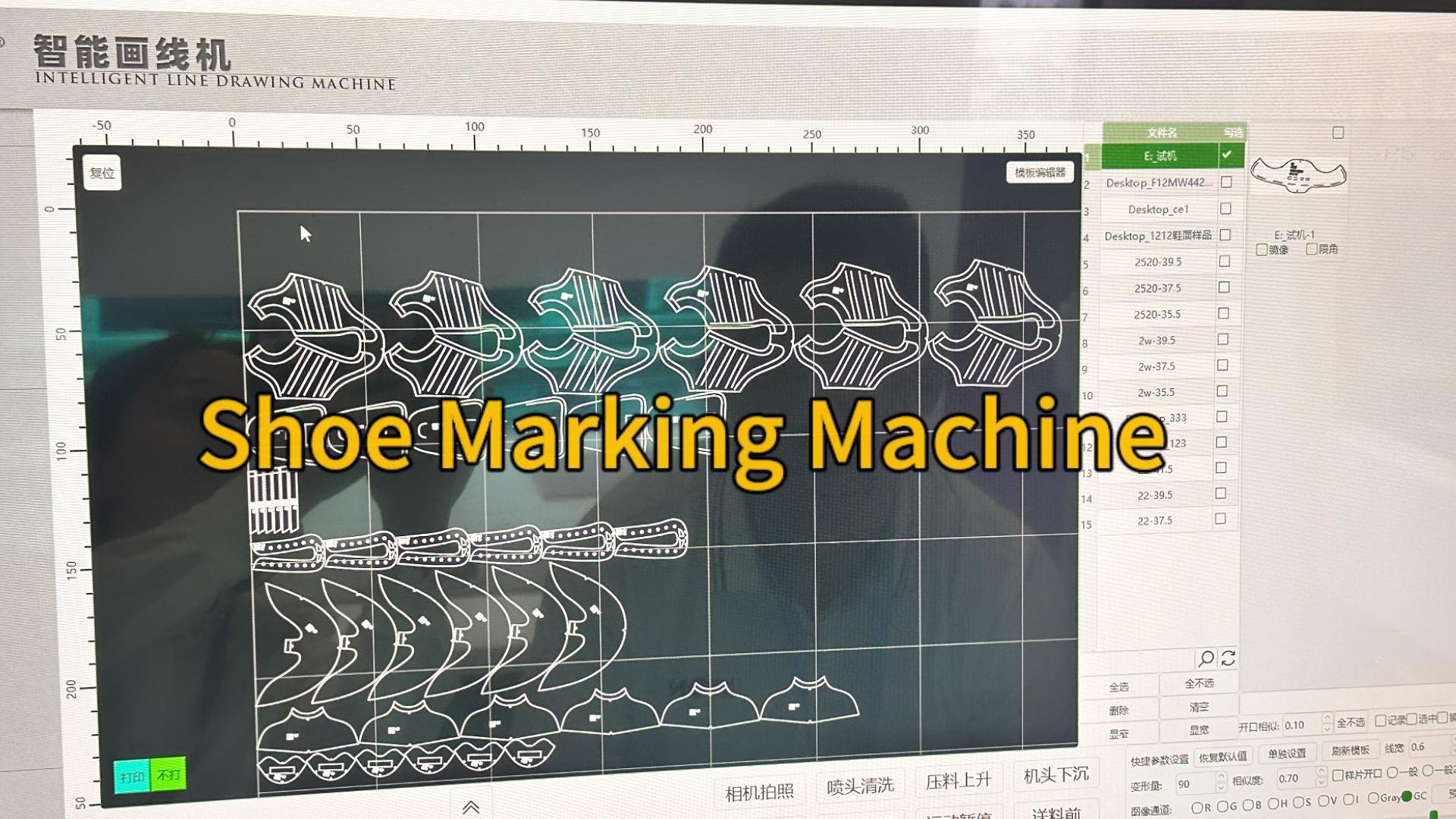

IBON answered this call with a cutting-edge solution integrating three breakthrough technologies: piezoelectric dual-printhead inkjet, deep-learning vision positioning, and a fully digital workflow. The result? Daily marking capacity skyrocketing to 60,000 pieces with an accuracy of ±0.1mm, support for diverse materials and inks, and a complete redefinition of marking quality and productivity.

Why Traditional Marking Methods Fall Short and How IBON Innovates

MethodManual MarkingScreen PrintingIBON Shoe Marking MachineDaily Output~800 pieces/worker~8,000 piecesUp to 60,000 piecesChangeover TimeLong and cumbersome45 minutesUnder 30 secondsPrecision~±0.5mm±0.5mm±0.1mmInk OptionsLimitedBasic 3 colors12+ specialty inks (including fluorescent)CostsHigh labor cost$2,000+ mold costMold-free, saving ~$45,000/year

By eliminating molds and manual labor, IBON’s fully digital inkjet technology supports AI-generated design files for instant shoe model switching. Its piezoelectric dual-printheads operate at 120kHz, ejecting droplets as small as 5 microns. Combined with a 12MP industrial vision system and deep-learning algorithms, it rapidly recognizes and accurately positions randomly placed uppers for marking.

Setting a New Standard for Smart Footwear Marking

High Throughput: Mark up to 60,000 uppers daily, ideal for large-scale OEM/ODM production.

Flexible Customization: Handles multi-material assemblies like mesh, PU, TPU with perfect recognition and marking.

Eco-Friendly: Uses VOC-free inks and consumes 80% less energy compared to laser marking.

Digital Integration: Seamlessly connects with factory management systems for automated workflow and traceability.

AI visual Printer

Industry Adoption and Endorsements

IBON’s marking machines have been deployed in supply chains for global brands like Nike and Adidas, supporting iconic lines such as Air Jordan. Luxury brands like Gucci leverage its UV-fluorescent marking for invisible anti-counterfeiting features. Medical footwear manufacturers use the technology for pressure mapping on diabetic orthotics.

"IBON’s machine reduced our stitching rework by 37%, marking the most significant pre-sewing innovation in a decade."

— Dr. Elena Rossi, Production Director, Geox Italy

Conclusion

IBON’s shoe upper marking machine is more than just equipment—it’s the intelligent robotic partner empowering footwear factories to enter the era of Industry 4.0. By seamlessly blending digital precision, operational efficiency, and environmental responsibility, it solves long-standing marking challenges and sets footwear manufacturing on a new path of innovation.

Download IBON’s “Zero-Mold Marking Guide” and ROI Calculator to revolutionize your footwear marking process .