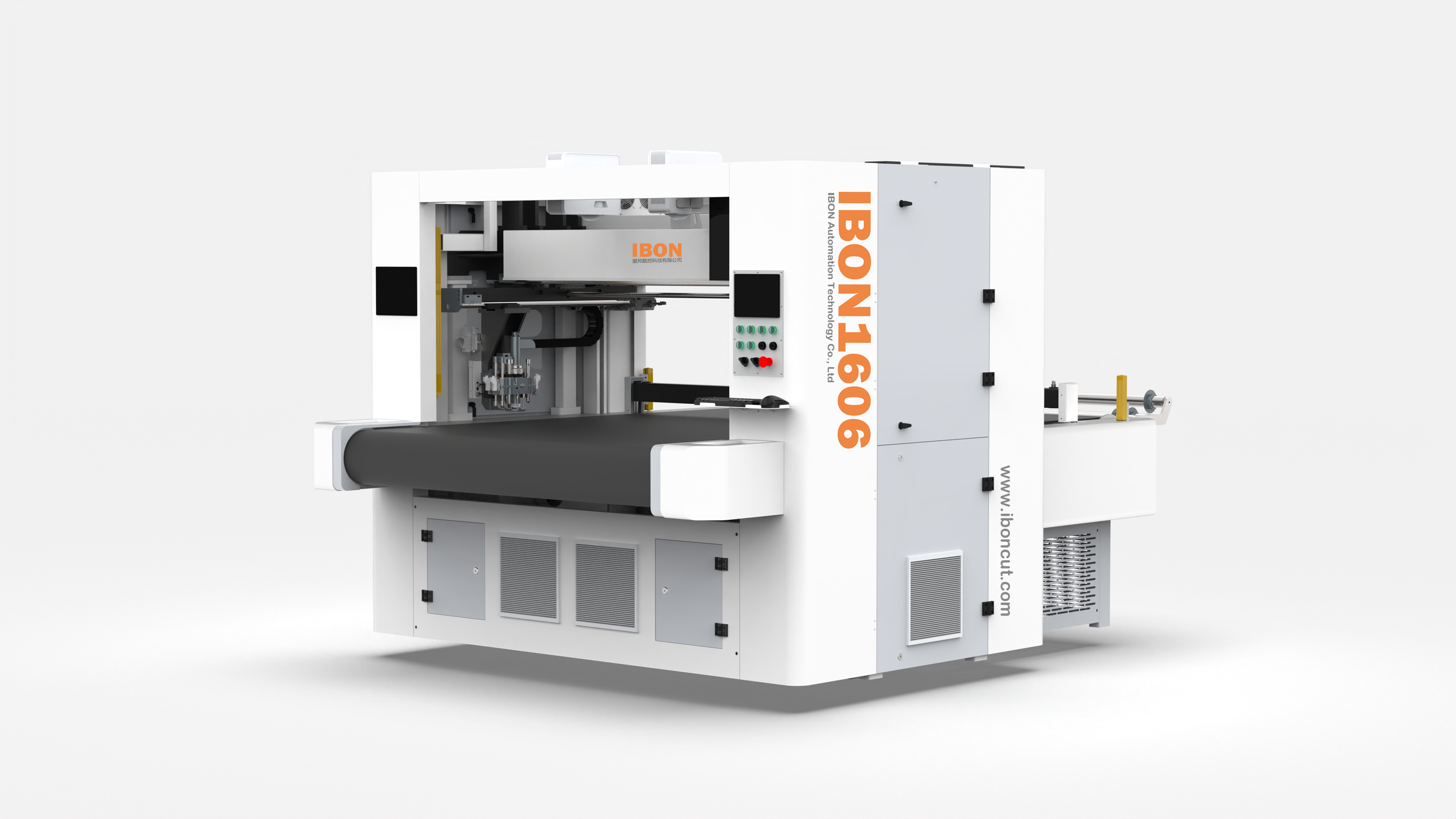

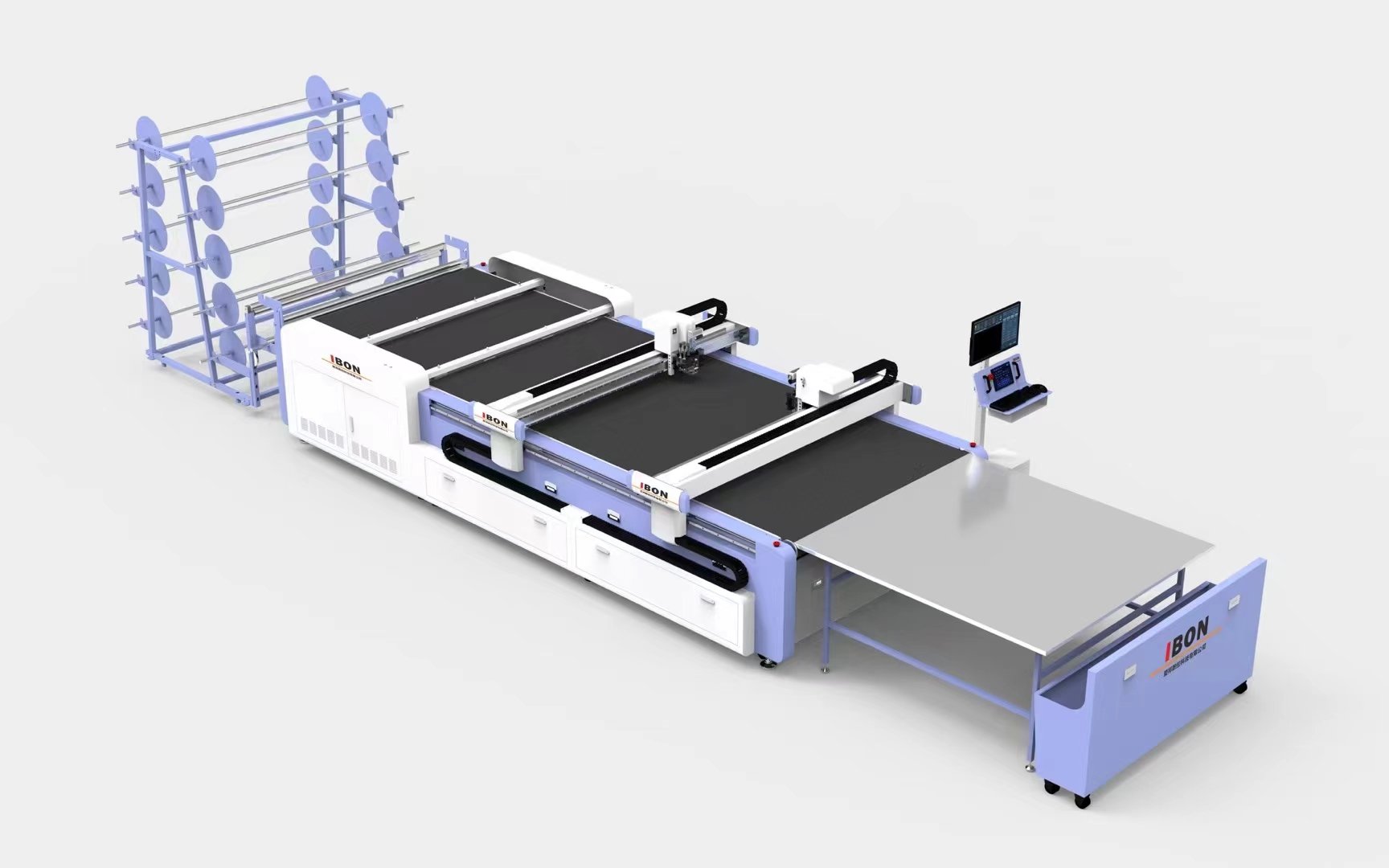

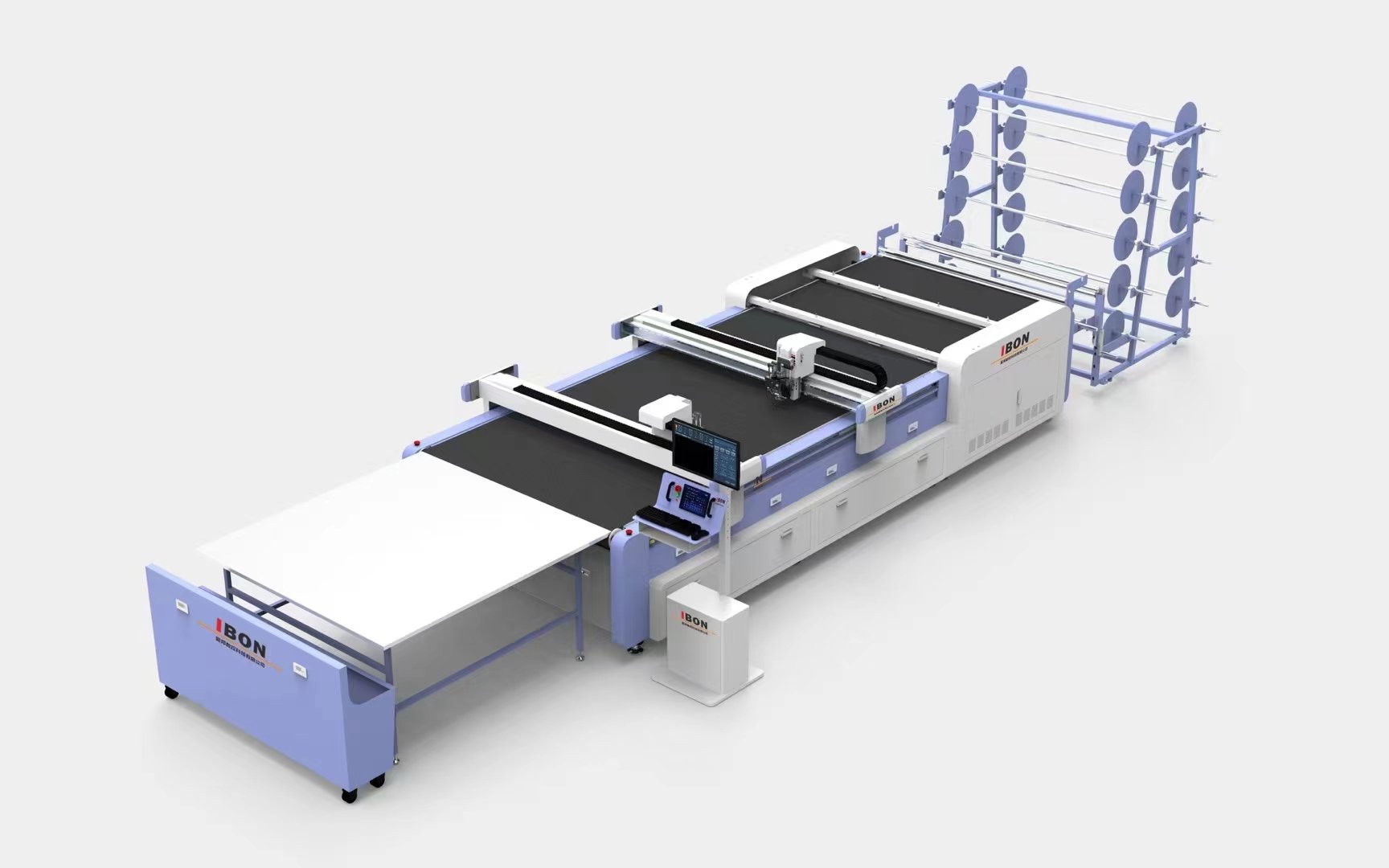

Product Description

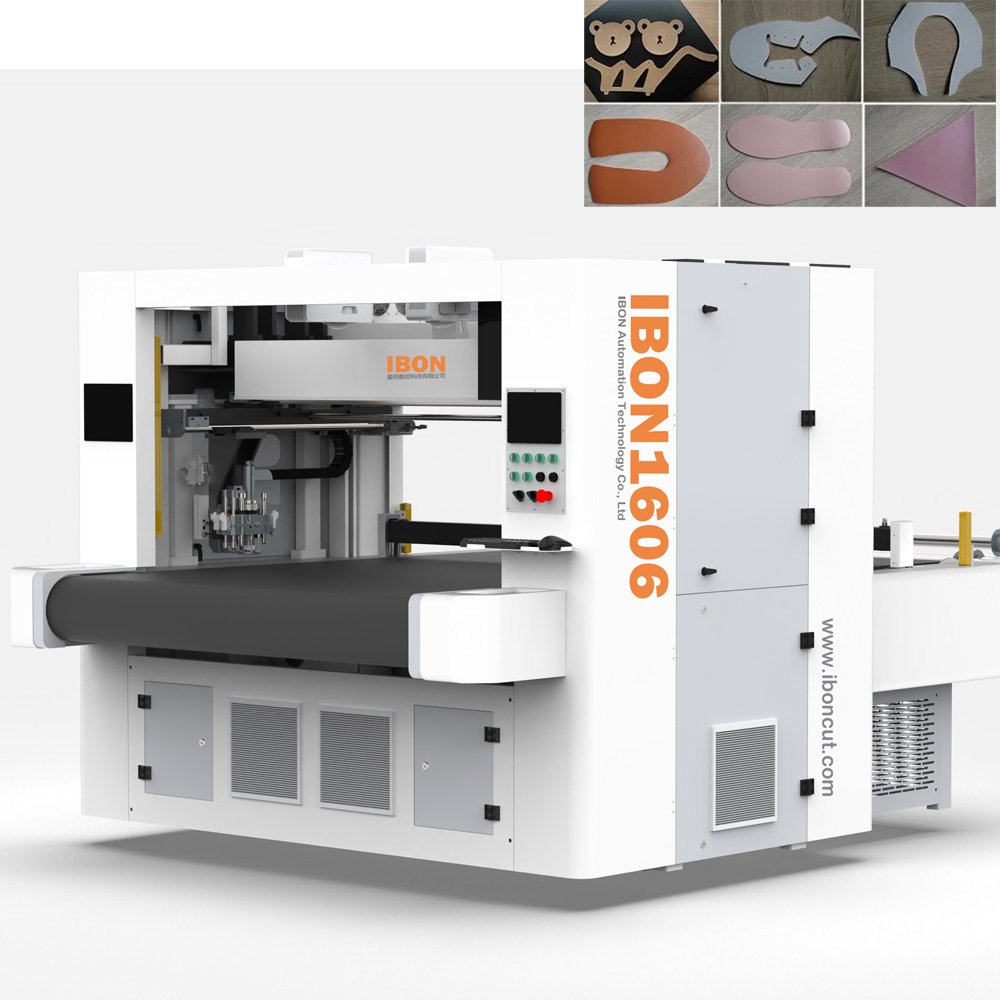

IB1606 Perfect for:

Leather and shoe components

Textile and fabric cutting

Composite materials

Automotive interiors

Apparel manufacturing

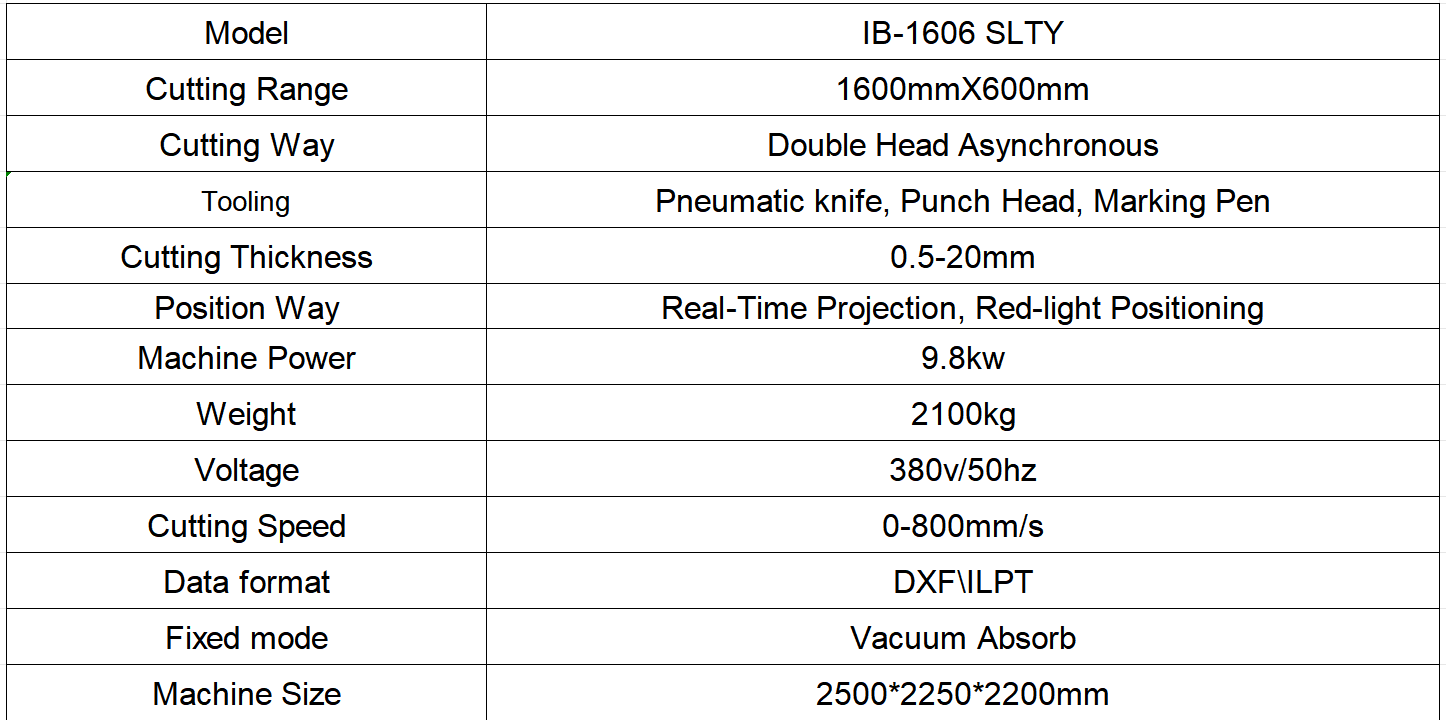

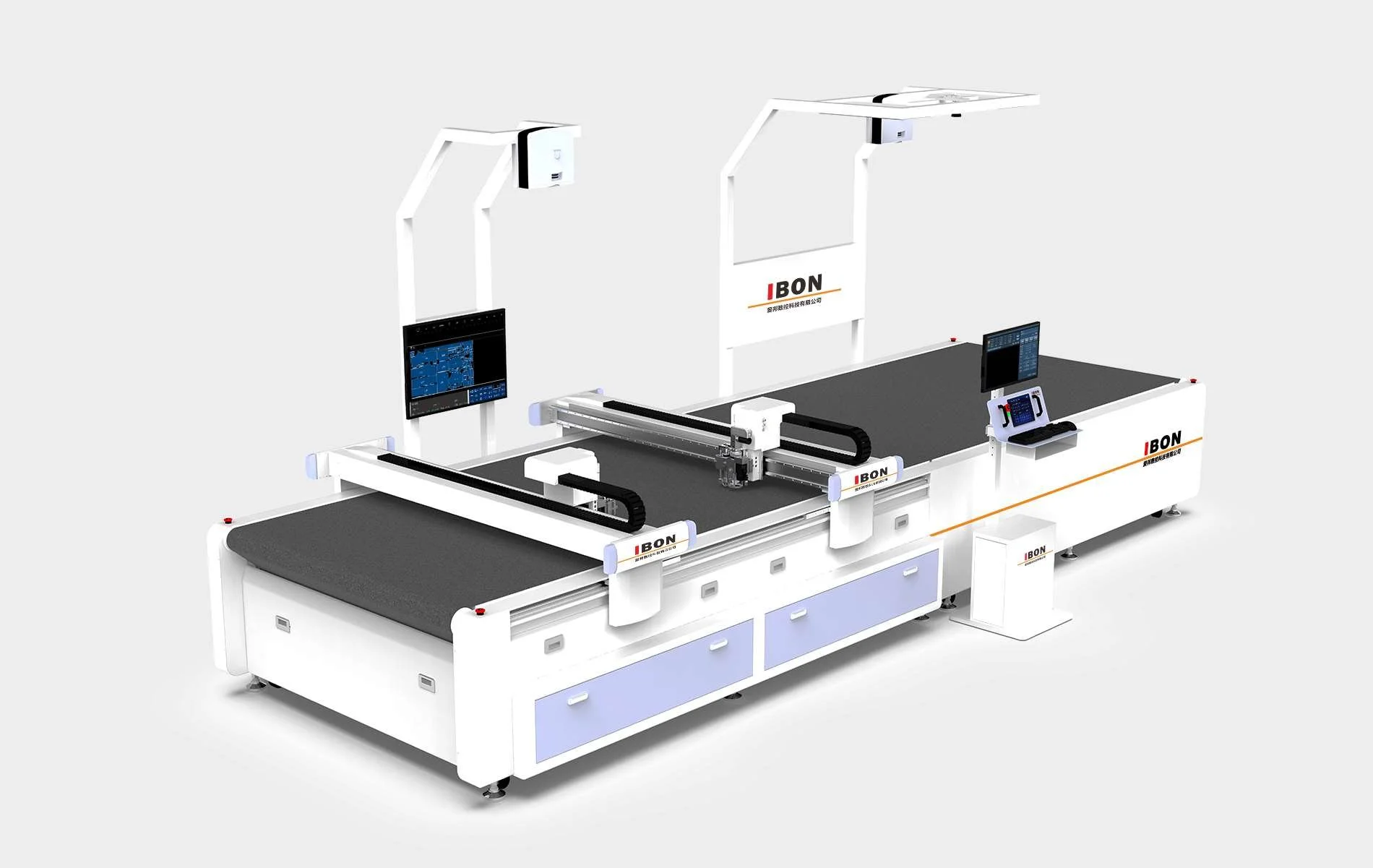

With dual-head asynchronous cutting, the system enables multi-layer, high-speed production, boosting efficiency while reducing material waste.

Compact yet powerful, the IB1606 delivers precise cutting for footwear and apparel accessories. It supports PU, TPU, mesh, and digitally printed materials, achieving effortless multi-layer and same-color cutting with superior accuracy.

Key Features:

One-Click Split & Sorting

Automatically marks cut and punch lines, then instantly sorts and sequences pieces by size — eliminating manual setup and reducing errors.

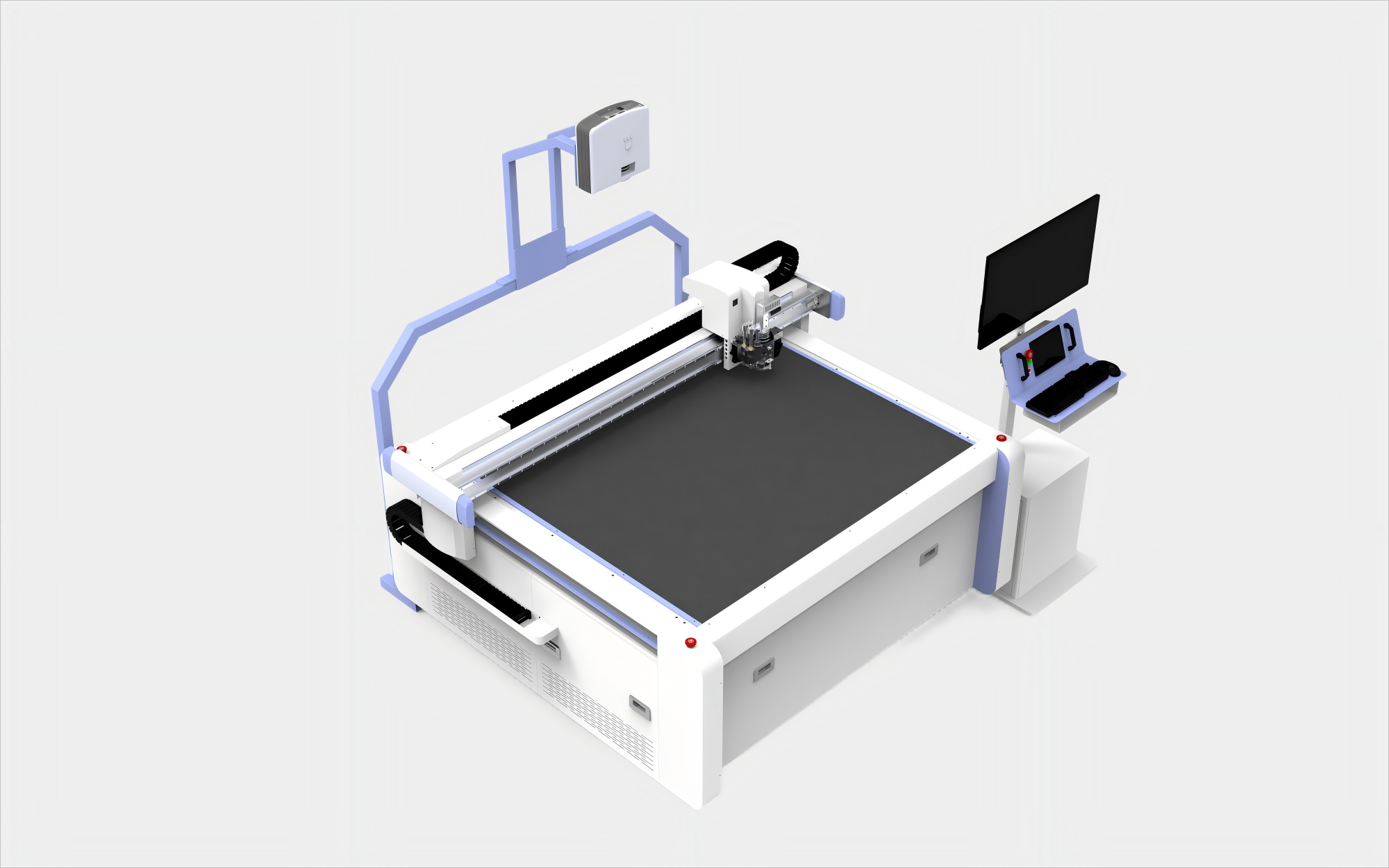

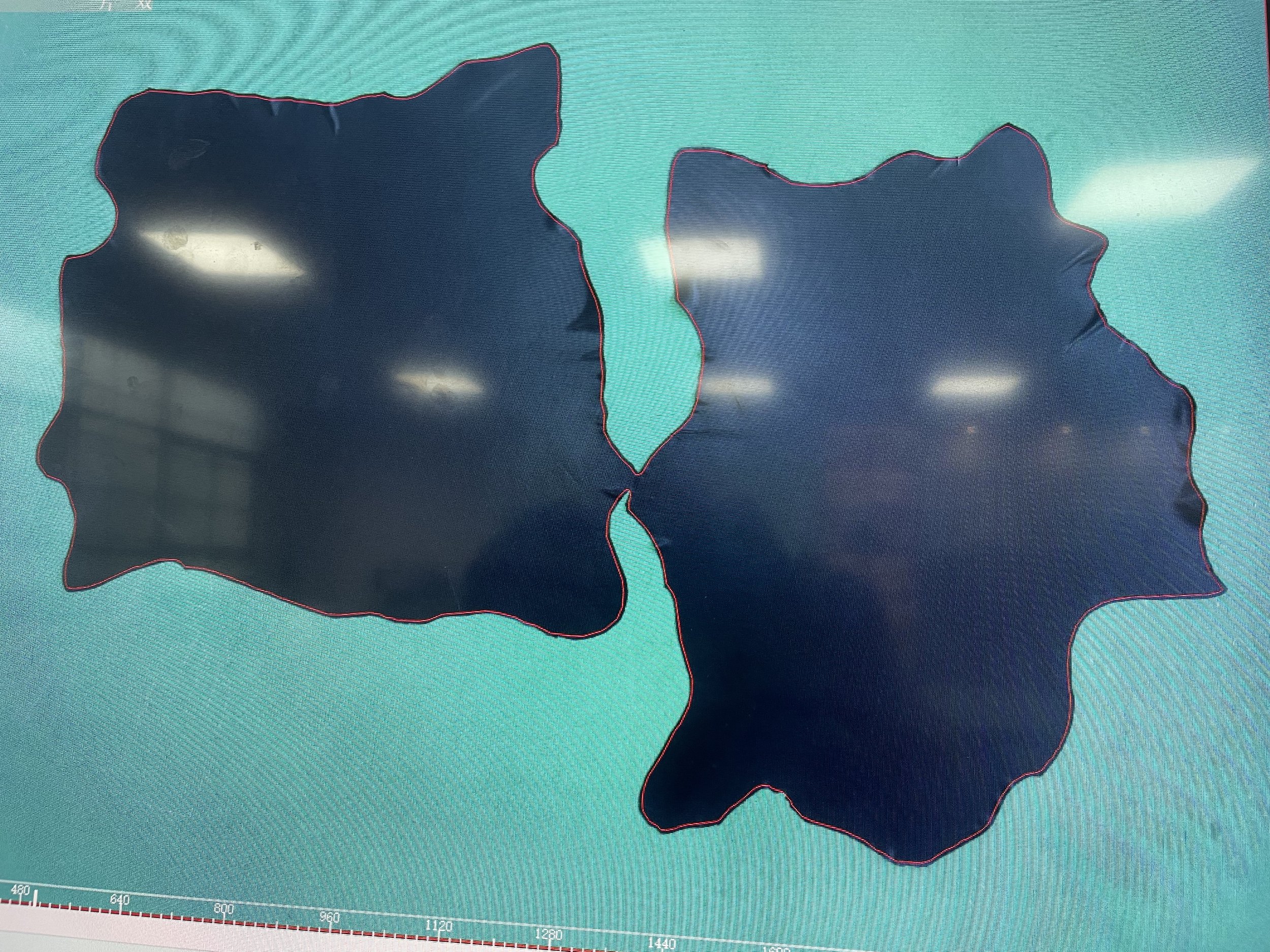

Projection Simulation Preview

Visualize the entire cutting layout on-screen before production to prevent costly mistakes and guarantee perfect alignment.

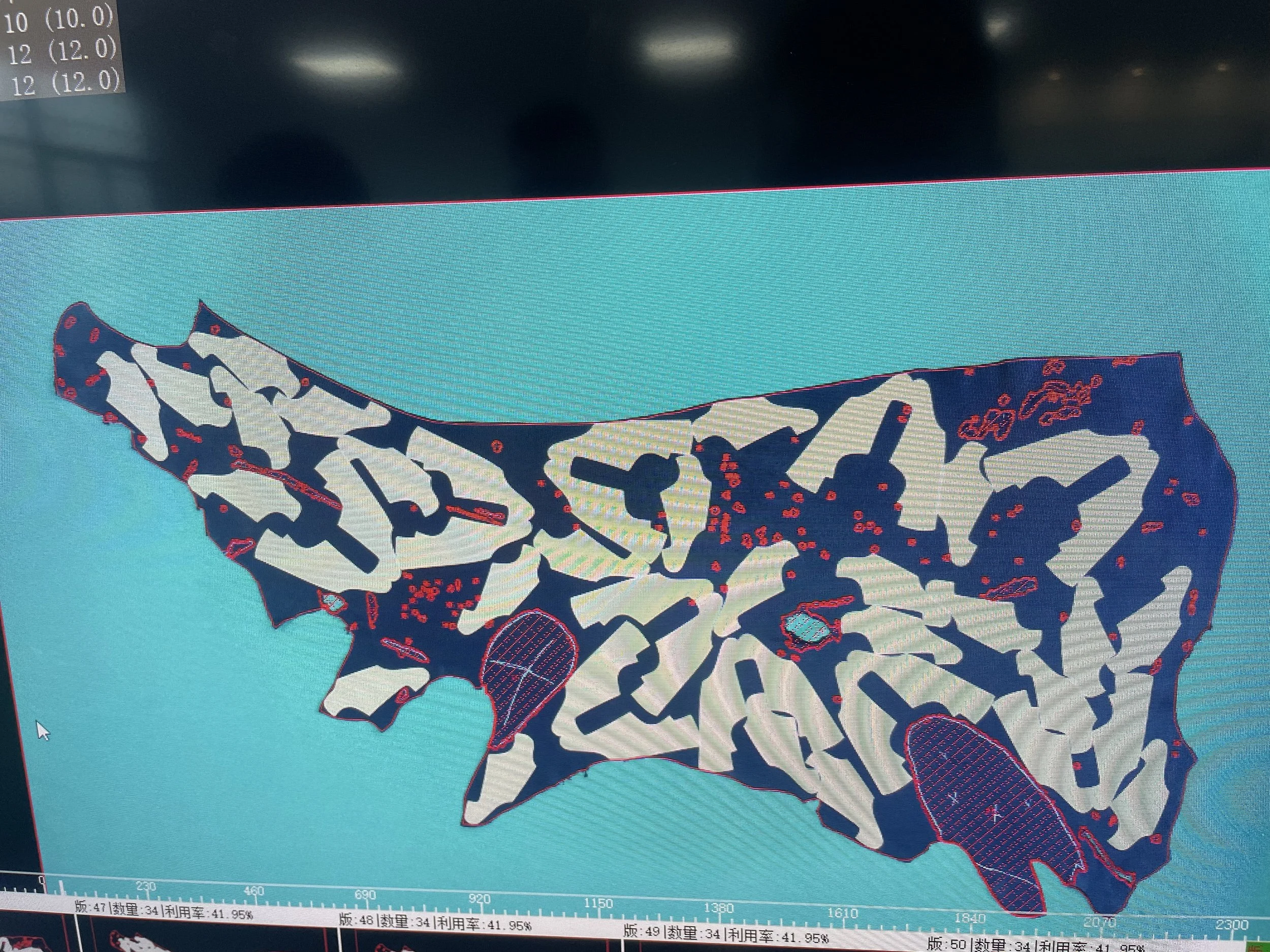

Ultra-Fast Nesting

Our intelligent nesting software processes up to 50 meters of material in just 2 minutes, maximizing material utilization and minimizing preparation time.

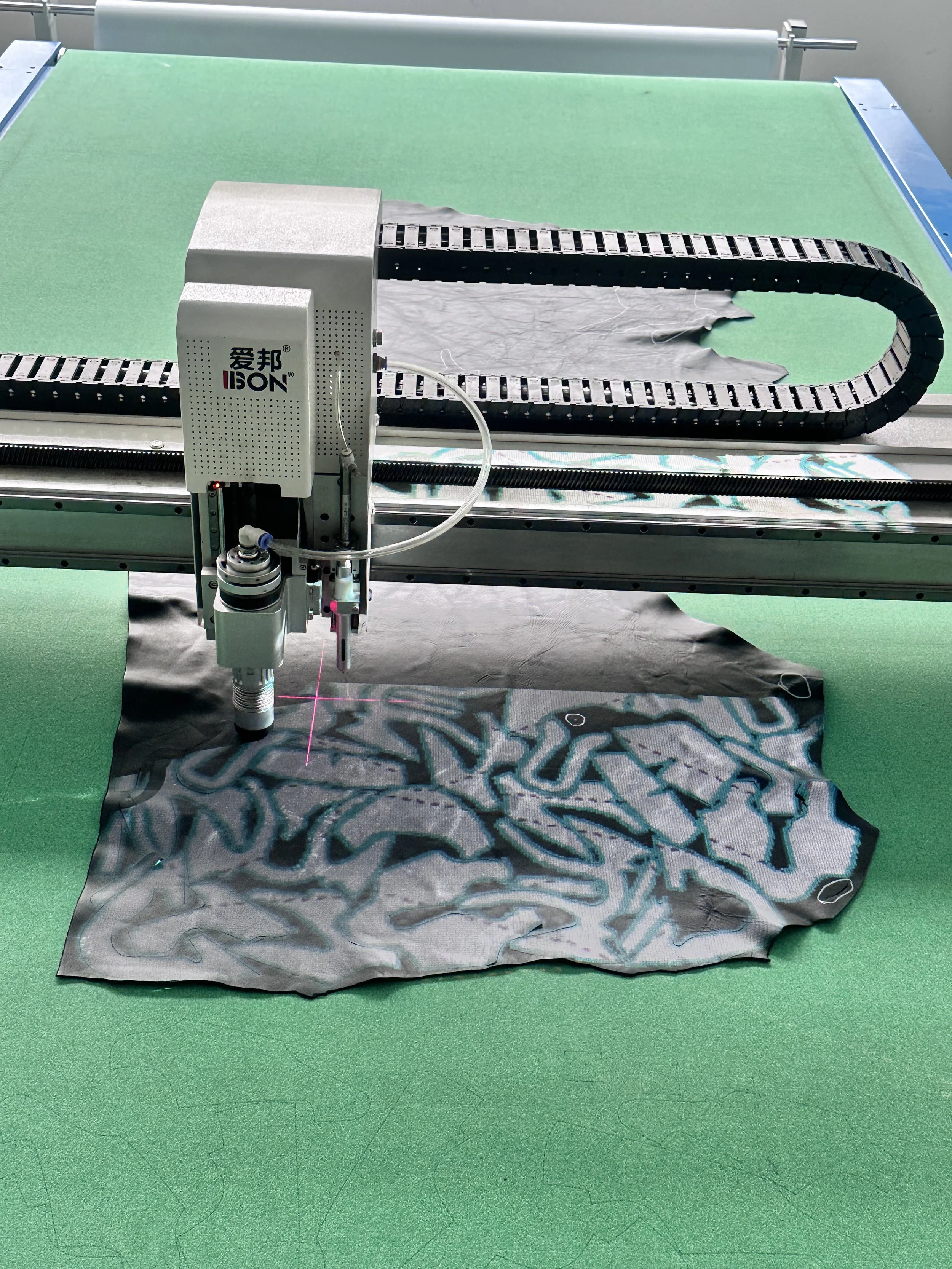

Visual-Align Cutting Technology

A high-definition camera captures printed contours and automatically corrects cutting paths through smart algorithms, delivering precise, edge-perfect results every time.

Packaging

Our warranty and After-sales Service:

1.Guarantee Period: One year warranty against delivery.

2.Spare Parts: All spare parts are available whenever needed.

3.Training: We provide one free operation training for our products in our office.

4.On the Spot Service: On the spot can be considered and arranged.

5.General Timeliness: Respond within 24 hours