How to Make Leather Easier to Cut?

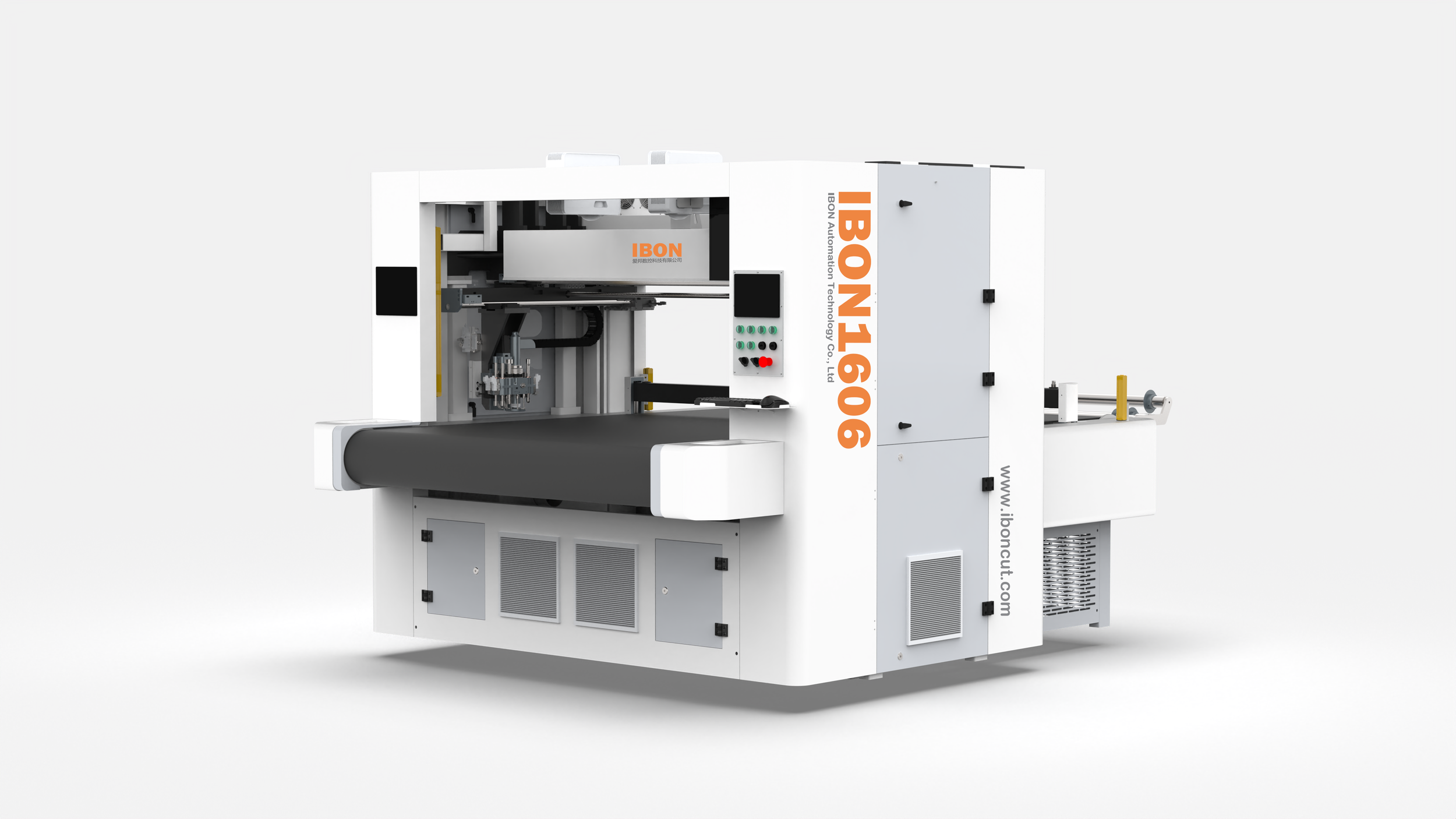

IBON proudly presents its state-of-the-art automatic leather cutting machine, engineered to make leather cutting easier, faster, and more precise.

In today’s competitive leather manufacturing industry, efficiency, accuracy, and flexibility are key.

Our IBON CNC leather cutting machine delivers all three — making it the ideal solution for both small custom batches and large-scale production lines.

Equipped with intelligent control systems and advanced automation, IBON helps manufacturers optimize workflow, reduce labor costs, and minimize material waste, taking leather production to the next level of digital efficiency.

India shoe mANUFACUTRER

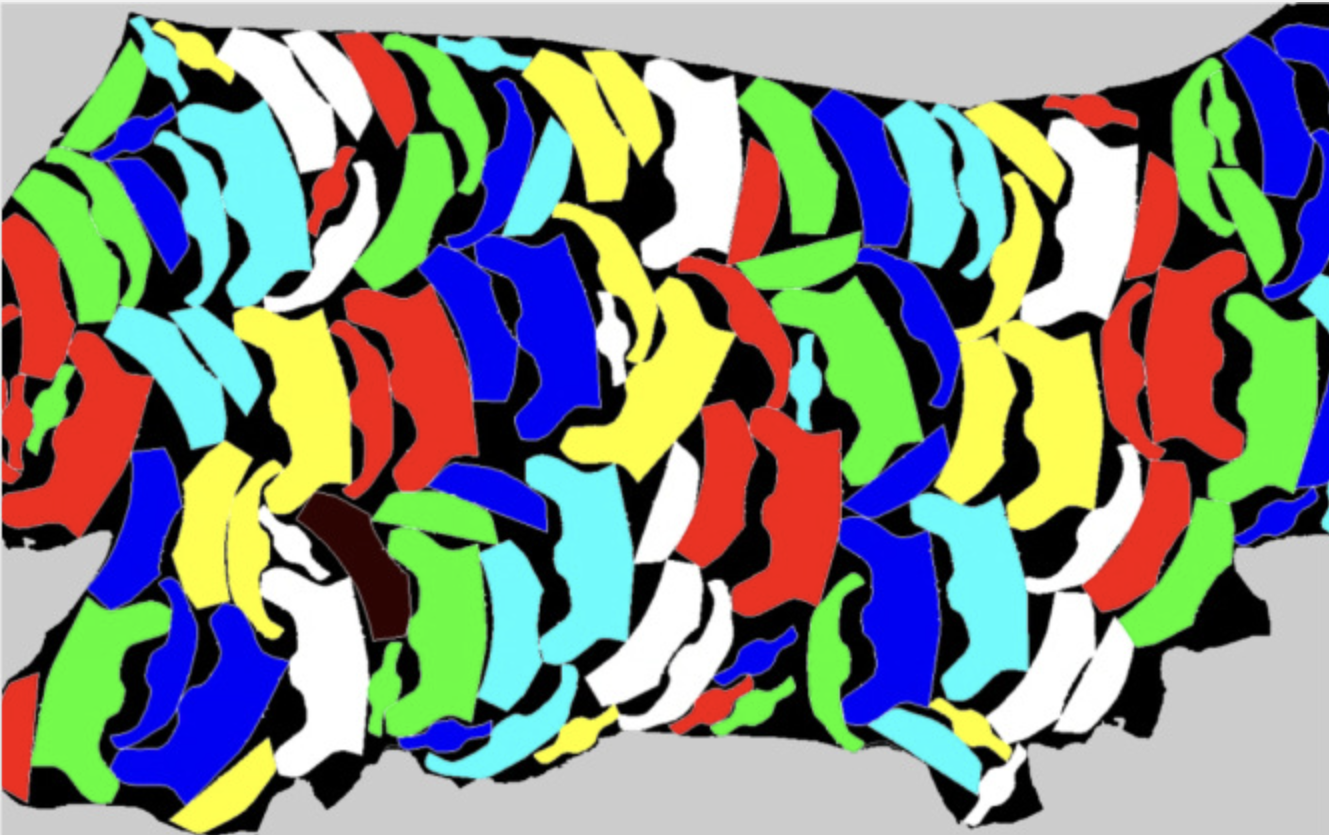

Bata India mastered the IBON 1606 cutting system in just one day, tackling key challenges like material waste and slow setup times. Its AI vision enables precise secondary cutting, while smart nesting and dual-head asynchronous operation drastically boost efficiency and reduce waste. This smart manufacturing solution delivered higher productivity, lower costs, and future-ready precision for competitive footwear production.

When a DIGITAL CUTTING MACHINE Meets the Realities of a Footwear Factory

In today’s competitive footwear industry, digital cutting machines are more than just high-tech tools—they’re problem-solvers. By combining precision shoe upper cutting, automated workflows, and reduced material waste, these CNC footwear cutting solutions are transforming everyday challenges on the factory floor into opportunities for higher efficiency and better quality.

Global Footwear Manufacturing in 2025

The Silent Crisis: Tariffs Are Eating Your Margins. Automation Is the Only Escape.

“When every second on the production line costs $0.01 in tariffs, the real battle shifts from labor costs to material efficiency and machine precision.”

Vietnam’s 20% tariffs. Indonesia’s 19%. Cambodia’s reprieve at 19% after brutal negotiations5. For factories, this isn’t policy—it’s survival arithmetic. Deckers absorbs $185M in tariff hits2; Nike bleeds $1B annually2. Meanwhile, India’s $0.9/hour labor lures brands—but without automation, low wages can’t offset 26% U.S. duties

Revolutionizing Footwear Manufacturing

Discover how IBON’s automated marking systems are transforming shoemaking across China. With AI-powered precision, factories like Fujian’s are cutting material waste, slashing labor costs, and accelerating custom orders — all while staying compliant with global sustainability standards. Join the $17B automation wave today.

How TO CHOOSE CNC knife cutting Machine ?

IBON's CNC oscillating knife cutting machine is the ideal solution for flexible, non-metal material cutting—such as PU leather, foam, carpet, and textiles. Powered by IBON’s self-developed software system, it offers unmatched precision, speed, and smart functions like auto nesting, contour recognition, and multi-tool compatibility. Built for automotive interiors, footwear, packaging, and more.

Unlock the Power of IBON Vibrating Knife Cutting Machines

IBON CNC Vibrating Knife Cutting Machines: Precision Heat-Free Cutting for Leather, Fabric, Foam & Composites.

Featuring smart AI nesting, quick-change tool heads, and eco-friendly operation – boost efficiency, slash waste, and revolutionize production across footwear, automotive, packaging, and industrial manufacturing.

Why We Don’t Discount

Don’t just chase the lowest price—invest in real value. At IBON, we help manufacturers achieve precision, speed, and cost-efficiency. Choose a partner that supports your growth. Choose IBON.

The Smart Robot Revolutionizing Footwear Manufacturing

Discover how IBON’s automated shoe upper marking machine is revolutionizing pre-sewing in footwear factories. With 60,000-piece daily output, ±0.1mm accuracy, and zero mold costs, it’s the smart robotic upgrade every modern shoe factory needs.