Product Description

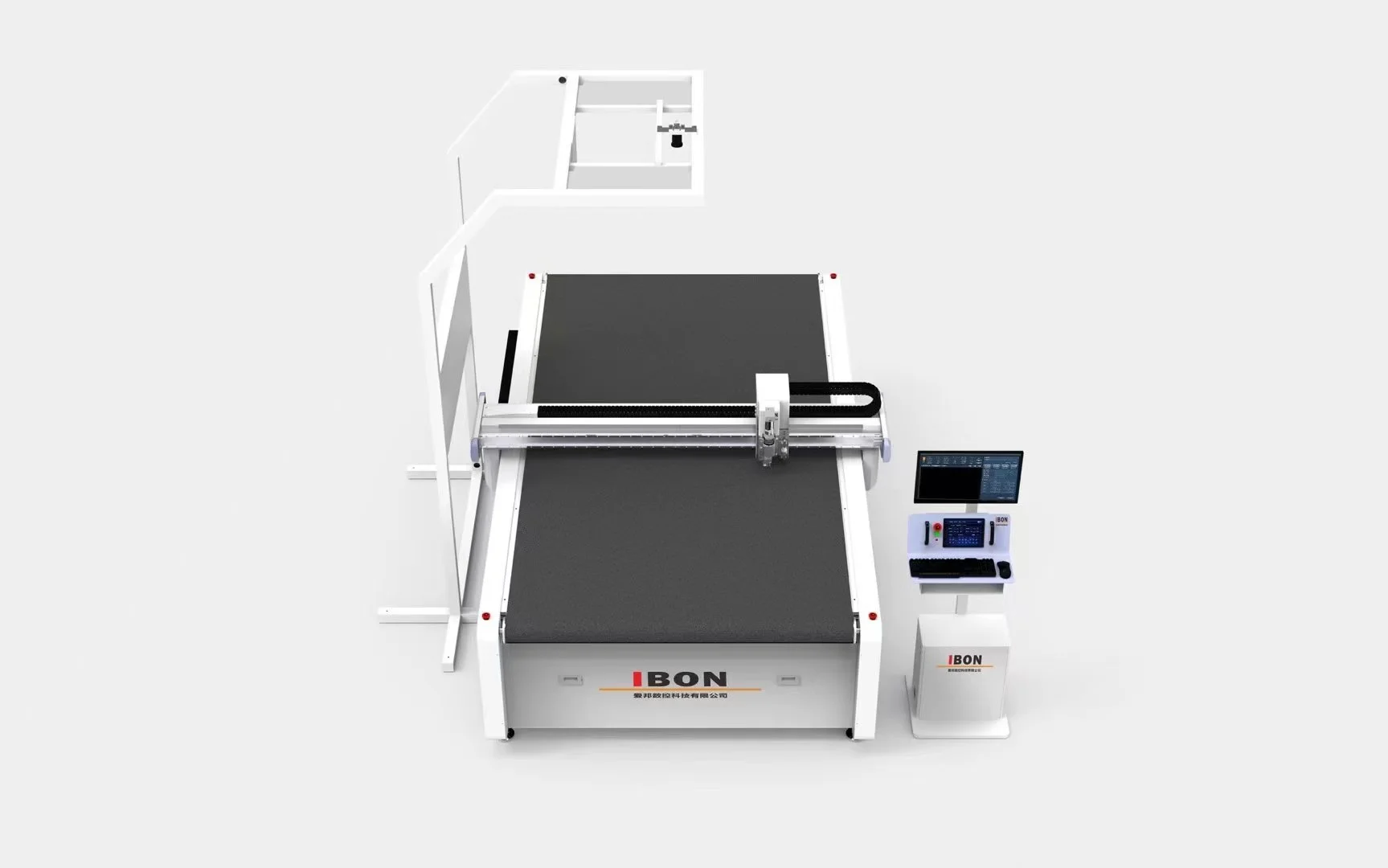

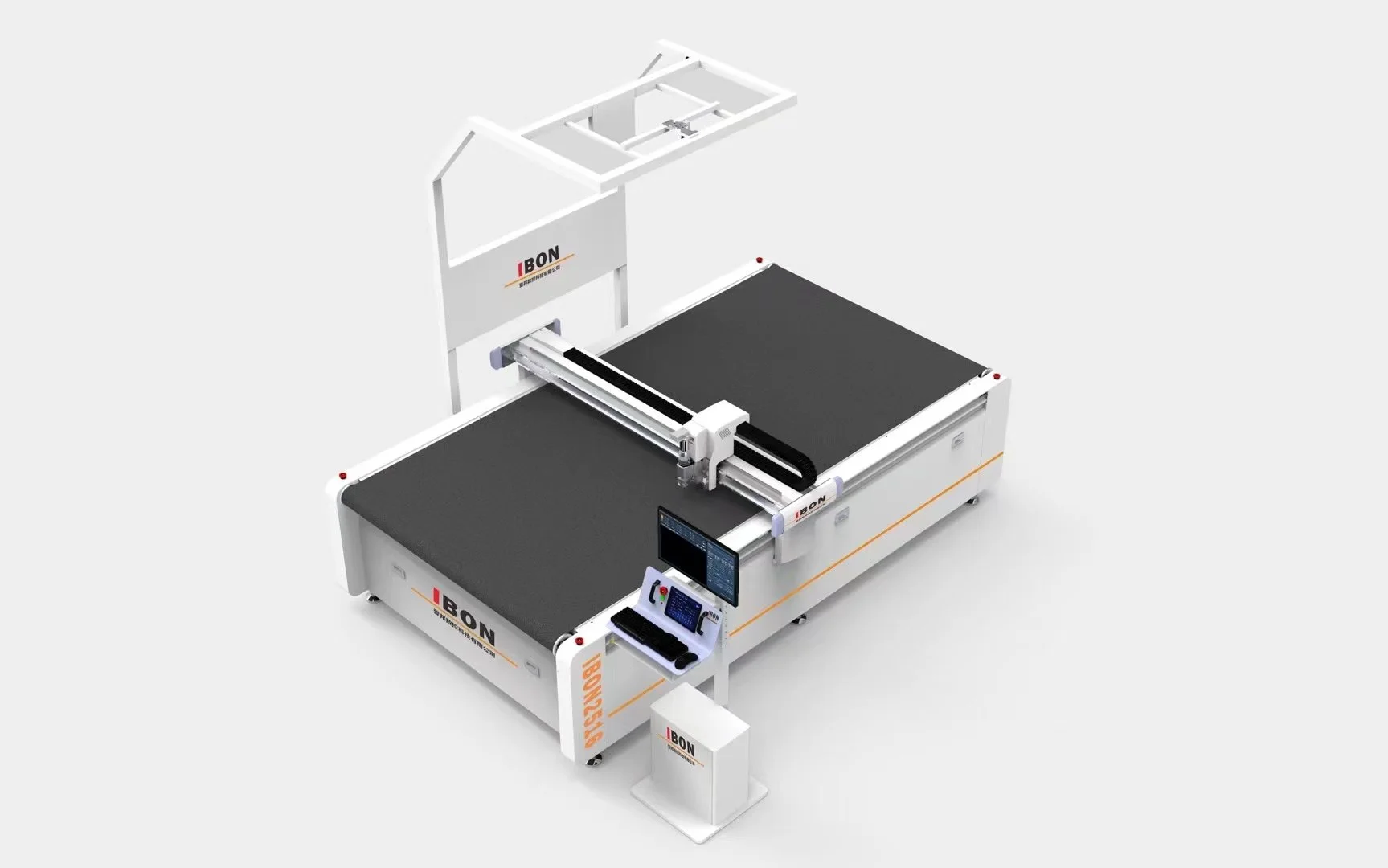

IBON 1625 offers precise, small-batch, and multi-layer cutting with projection positioning and an integrated knife holder for maximum material use and efficiency.

Its casted body and gear-driven motion ensure long-term precision and stability. Compact yet powerful, it suits mini production lines, labs, and R&D centers.

Equipped with imported servo motors (±0.01mm accuracy) and an intelligent feeding system for continuous, one-stop cutting.

The self-developed control system supports lifetime free updates and DXF file compatibility.

Perfect for samples or mass production, it enables fast, flexible, die-free cutting with smooth, burr-free edges.

Key Features

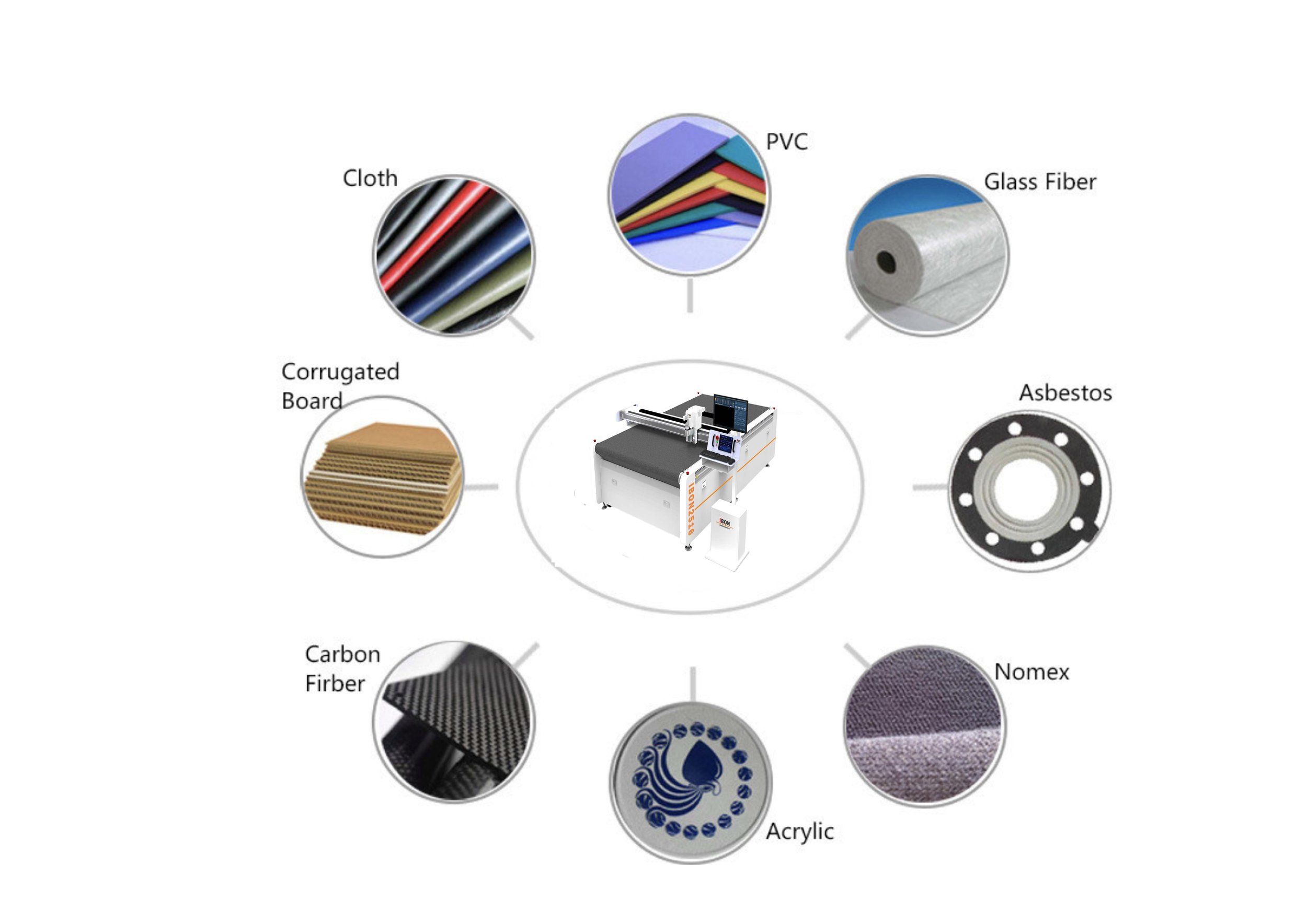

✔ Broad Material Compatibility

Cuts a wide range of materials including silicone, PVC, graphite, rubber, foam, non-asbestos, cork, and PTFE.

✔ High Precision

Delivers cutting accuracy up to ±0.05mm with clean, burr-free edges.

✔ Fast & Efficient

Advanced servo motors enable cutting speeds up to 2000mm/s, improving productivity.

✔ Multi-Tool Support

Compatible with oscillating knives, pneumatic knives, creasing, and milling tools to meet diverse cutting needs.

✔ Easy Operation

User-friendly control system supports DXF, PLT, and AI formats for seamless workflow.

✔ Safety First

Built-in infrared sensors and emergency stop ensure safe operation.

Cutting Materials

IBON CNC Cutting Machine — Configurations and Options

Standard Cutting Head

All IBON models come with one standard cutting head equipped with a variety of tools — oscillating knife, hobbing cutter, pinch roller, and pen.

This setup enables cutting, creasing, and marking on a wide range of flexible and packaging materials.Optional Dual-Head Configuration

For higher efficiency and expanded functionality, an additional cutting head can be added upon request.

This allows for milling, V-cutting, and punching, meeting diverse production needs.Automatic Feeding System (Optional)

Larger models such as IB1625 can be upgraded with an automatic feeding system for continuous cutting, ideal for batch or roll material processing.

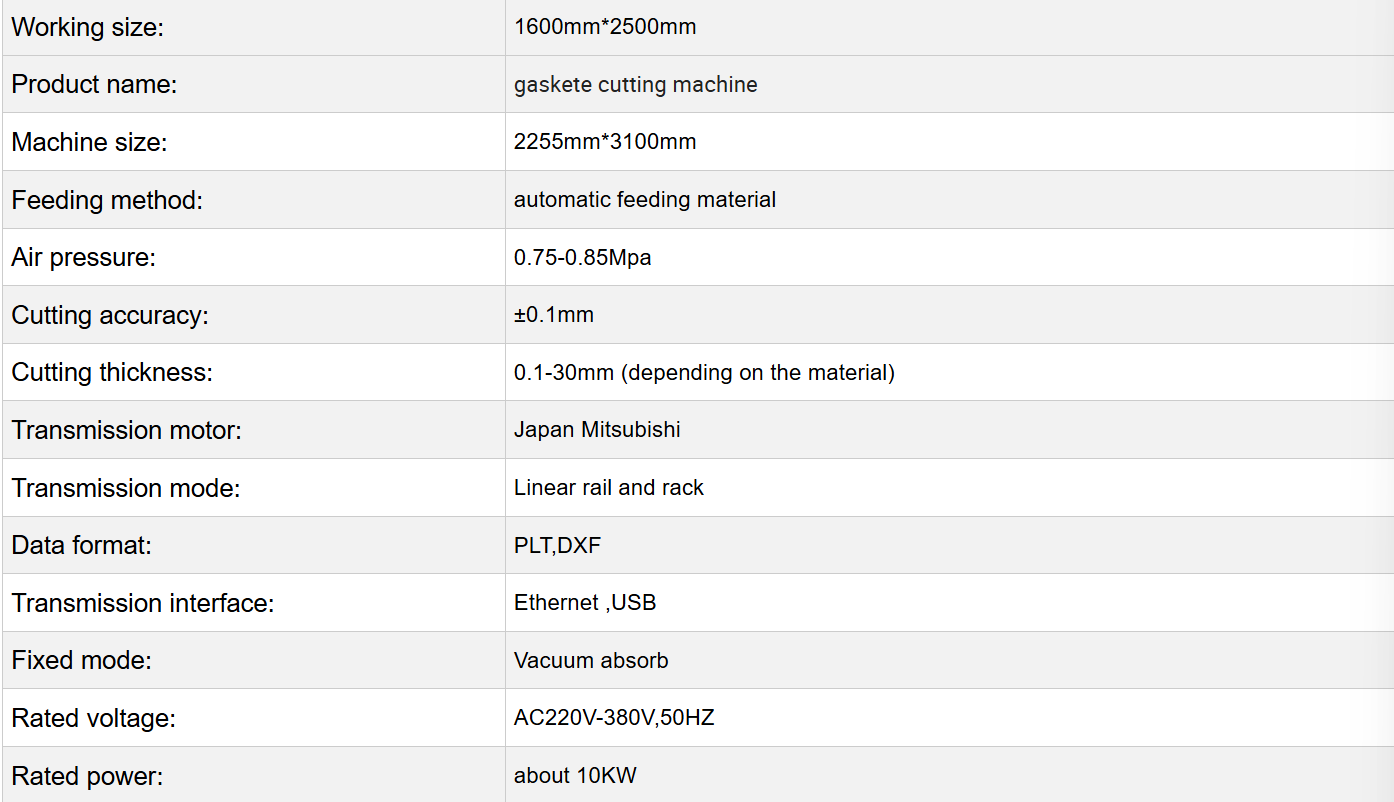

Available Cutting Sizes and Configurations

Model Cutting Size (mm) Cutting Head & Arm Feeding System

IB1410 1400 × 1000 1 & 1 No

IB1813 1800 × 1300 1 & 1 No

IB1625 2500 × 1600 1 & 1 No

IB1625A 2500 × 1600 1 & 1 Yes

IB1630 3000 × 1600 1 & 1 No

IBON Shows

Dongguan IBON Automation Technology Co., Ltd. is a National Torch Plan High-Tech Enterprise specializing in the R&D, production, sales, and technical service of

intelligent CNC cutting machines for flexible materials. IBON is committed to providing intelligent, automated cutting solutions and integrated production systems for flexible material industries.

Through continuous innovation, IBON enables the seamless integration of informatization and industrialization, helping manufacturers achieve smarter, more efficient, and fully digitalized production.

Certifacte

CE, ISO9001 certified,

Design patent certifications,

Utility model patent certifications,

Software copyright certifications.

TOP 10 Footware Machinery Enterprise,

TOP 10 Innovative Enterprise,

CTP(China Torch Plan) Key New High Technology Enterprise.

etc.

Shoe Machinery Exhibition

IBON CUTTING MACHINERY – FAQ

1. Are you a factory or trading company?

We are a professional CNC cutting machine manufacturer with over 10 years of experience, specializing in high-end digital leather cutters for flexible materials.

2. Can the machine be customized?

Yes. Our experienced design team can tailor solutions based on your material, size, and production needs to ensure the best cost-performance.

3. What’s the difference from laser cutting machines?

IBON knife cutters use oscillating blades—no laser, no smoke, no burn marks—ensuring smooth edges and a cleaner working environment.

4. What’s the warranty?

We provide a 24-month warranty. Core parts are free if quality issues occur. Lifetime technical support is included.

5. Do you offer service after the warranty?

Yes, IBON offers lifetime remote technical support and spare parts supply.

6. It’s my first time buying from China. Can you help?

Yes. We provide DDU door-to-door delivery and full setup guidance for new buyers.