Image 1 of 7

Image 1 of 7

Image 2 of 7

Image 2 of 7

Image 3 of 7

Image 3 of 7

Image 4 of 7

Image 4 of 7

Image 5 of 7

Image 5 of 7

Image 6 of 7

Image 6 of 7

Image 7 of 7

Image 7 of 7

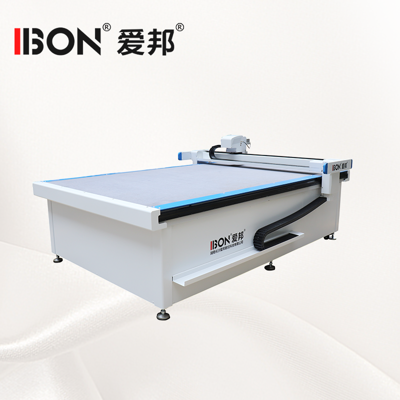

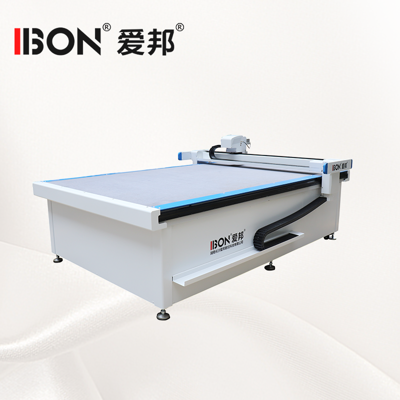

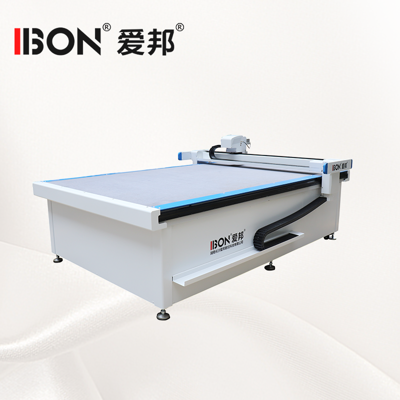

IB1625 IBON Fully Automatic Corrugated Carton Cutting Machine

With over 10 years of experience in the CNC cutting machine industry, IBON has become a leading force in China’s packaging box cutting machine sector through continuous technological innovation and talent development.

With over 10 years of experience in the CNC cutting machine industry, IBON has become a leading force in China’s packaging box cutting machine sector through continuous technological innovation and talent development.

Product Description

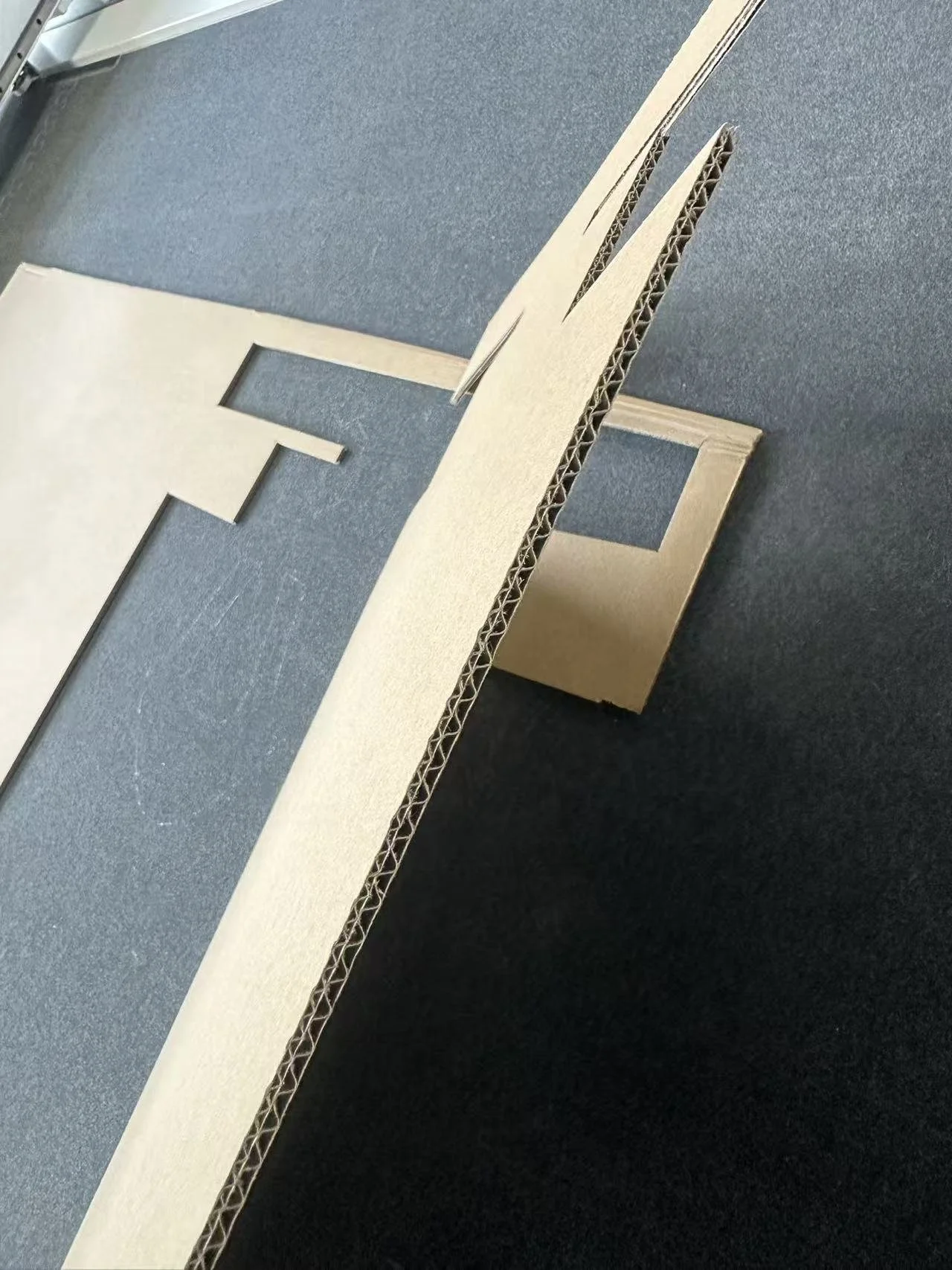

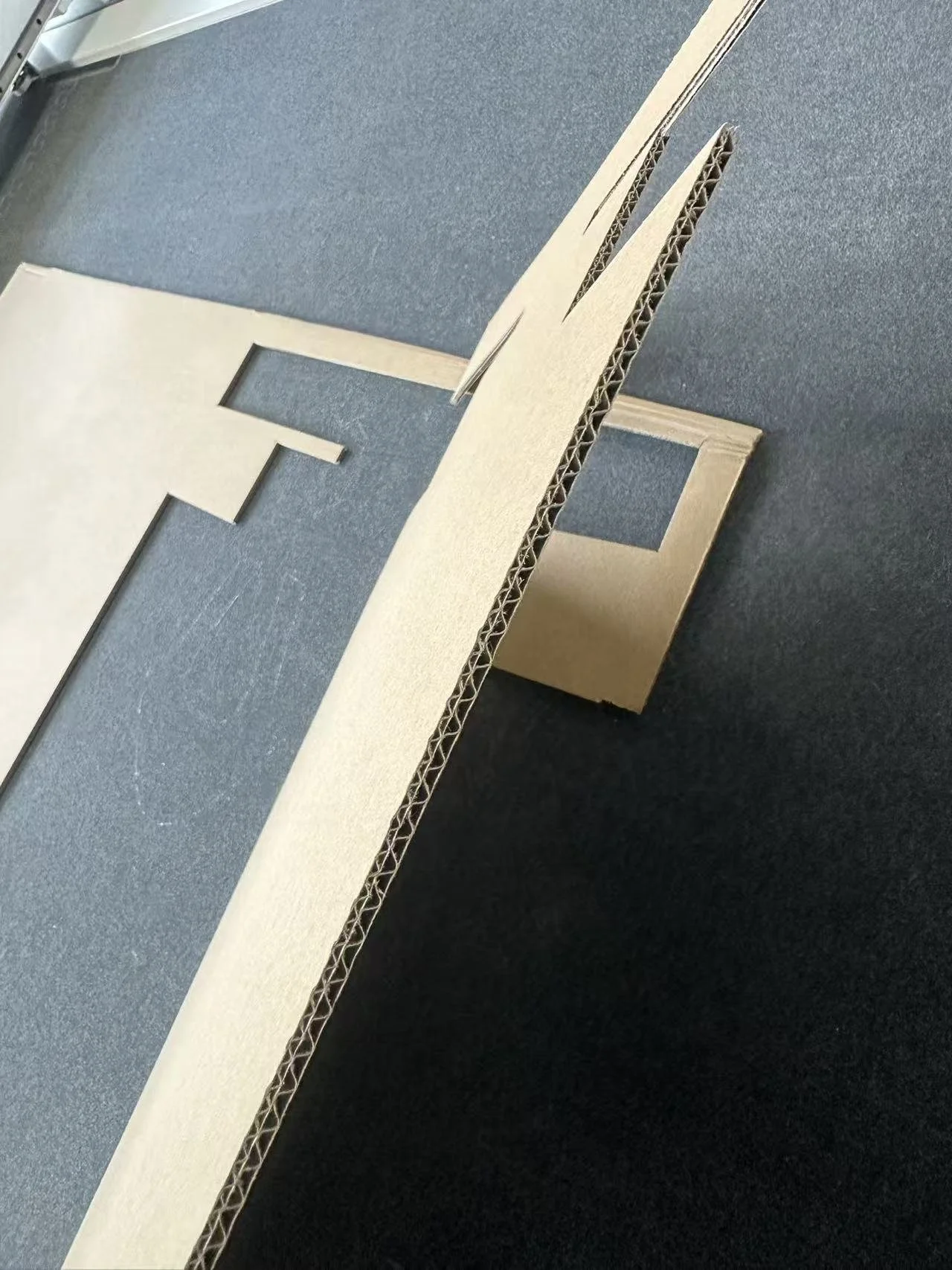

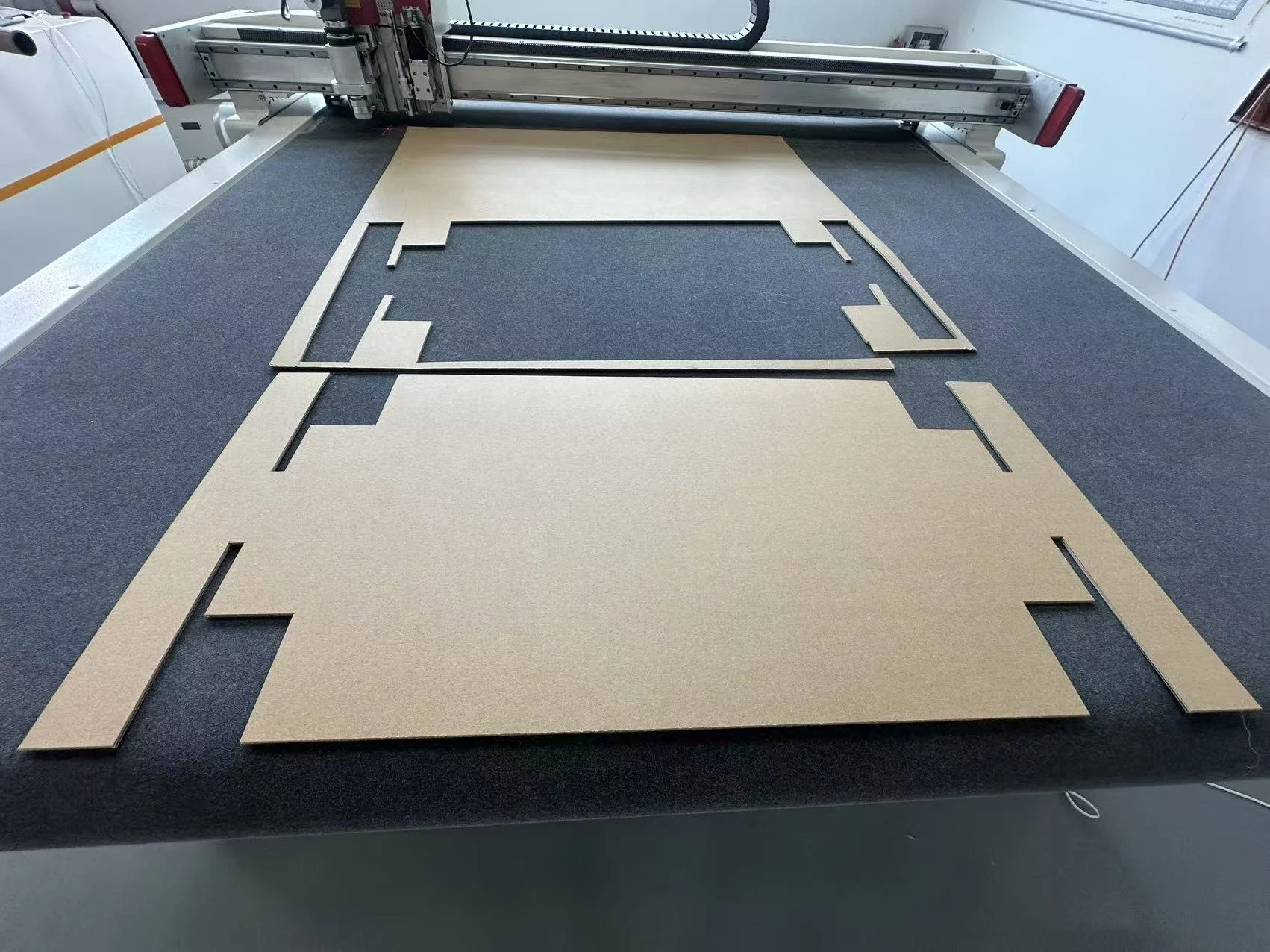

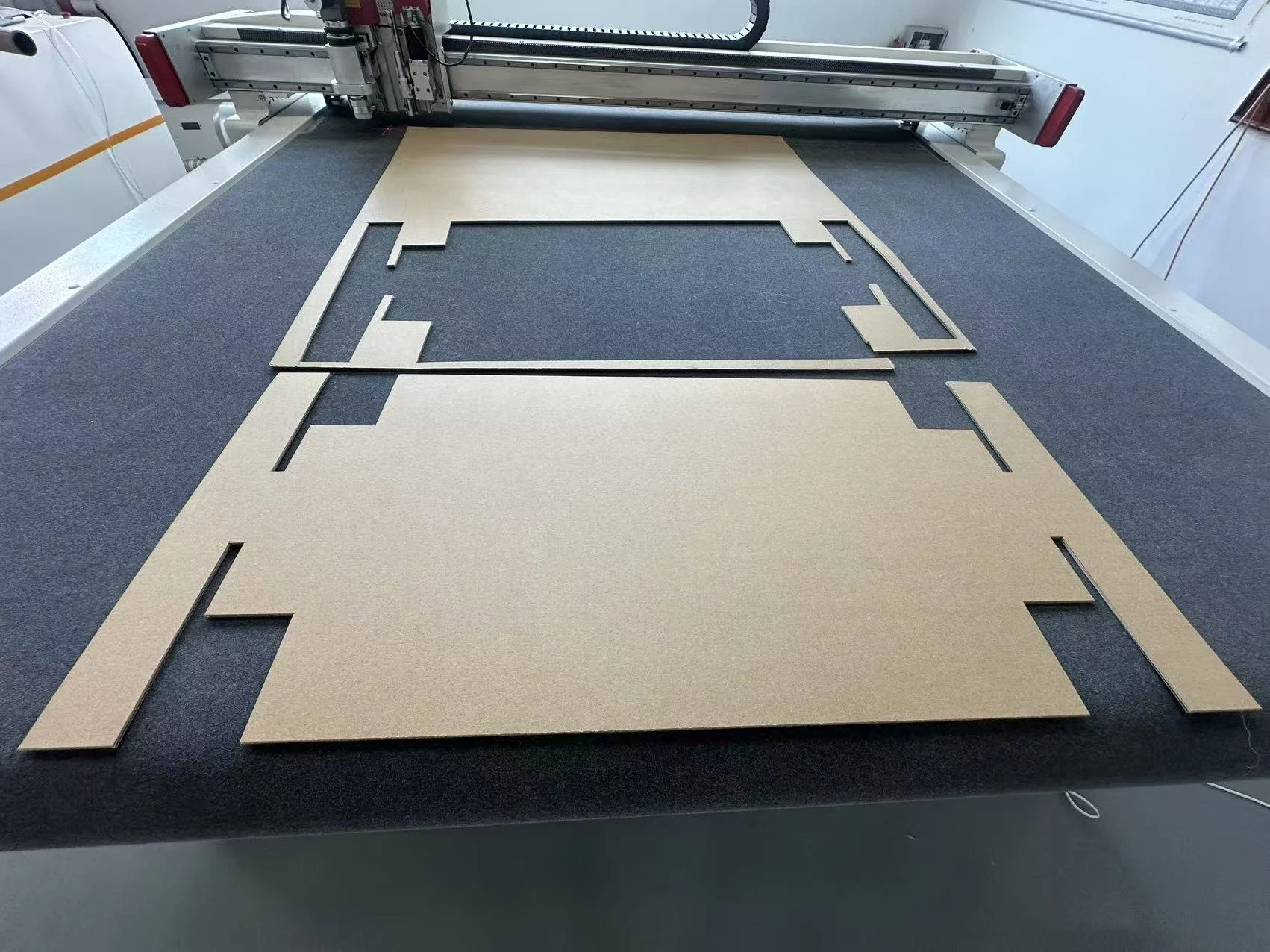

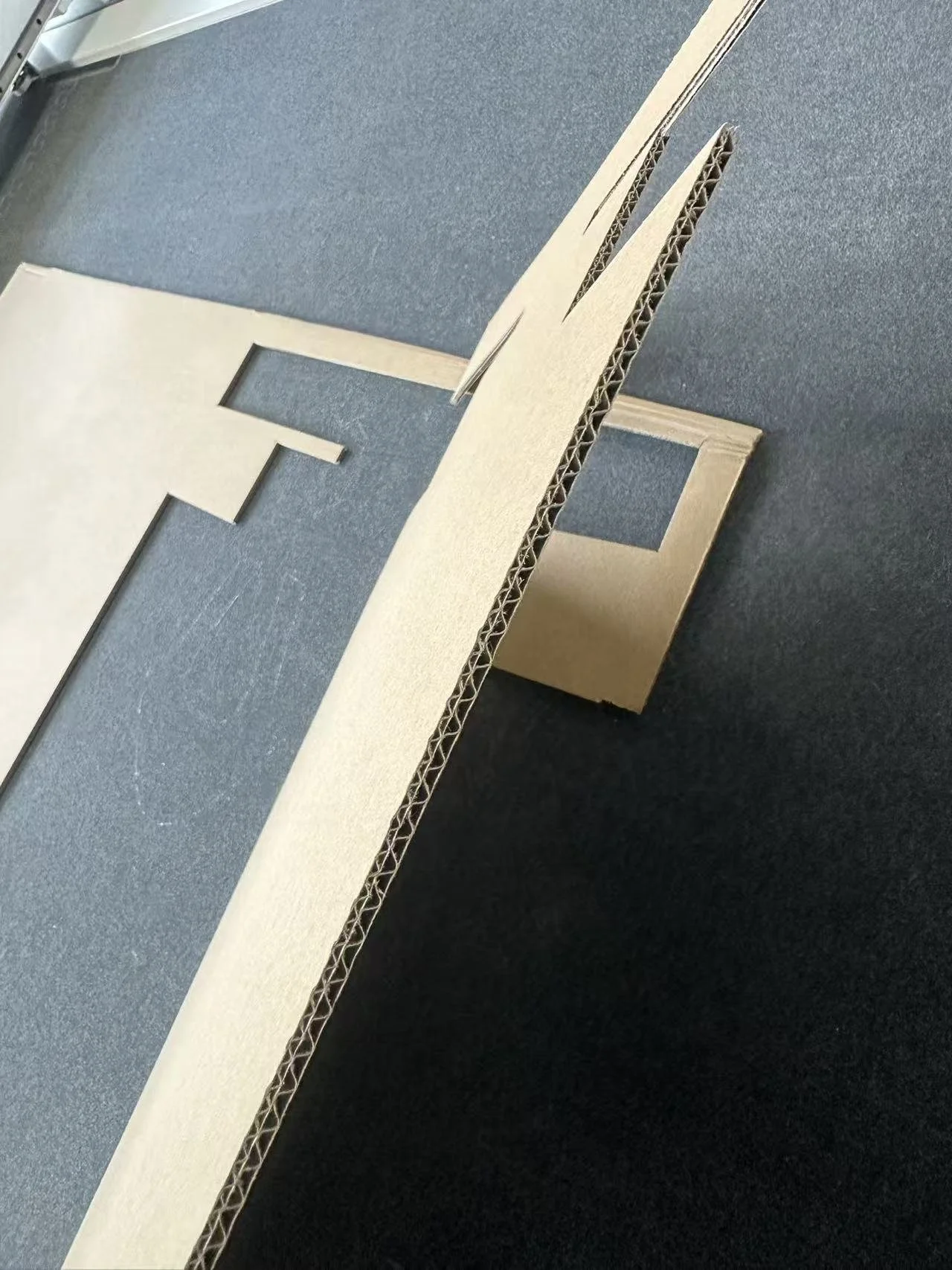

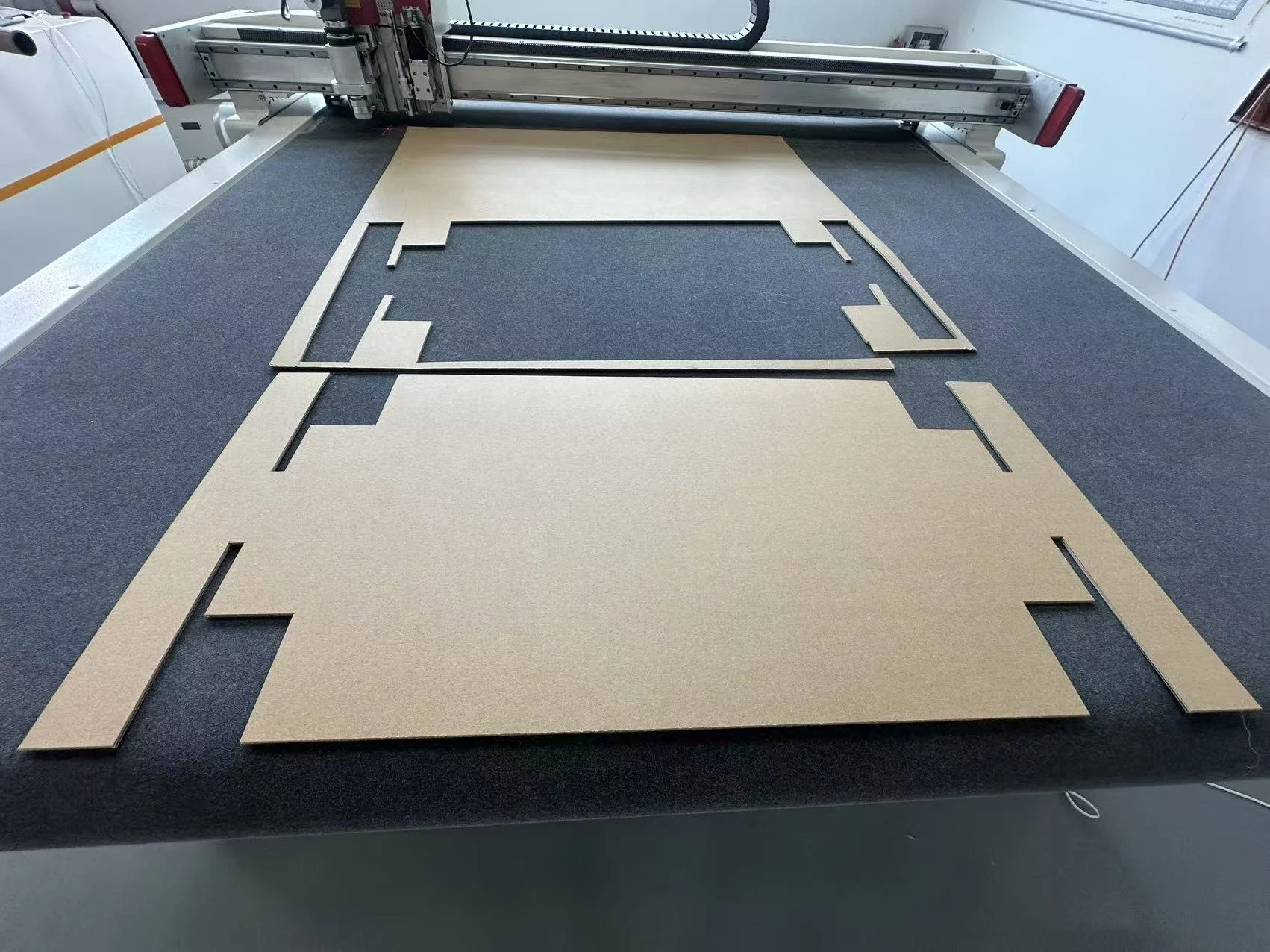

IBON 1625 offers precise, small-batch, and multi-layer cutting with projection positioning and an integrated knife holder for maximum material use and efficiency.

Its casted body and gear-driven motion ensure long-term precision and stability. Compact yet powerful, it suits mini production lines, labs, and R&D centers.

Equipped with imported servo motors (±0.01mm accuracy) and an intelligent feeding system for continuous, one-stop cutting.

The self-developed control system supports lifetime free updates and DXF file compatibility.

Perfect for samples or mass production, it enables fast, flexible, die-free cutting with smooth, burr-free edges.

IBON Vibrating Knife Cutter — Smarter, Faster, Greener

The IBON Vibrating Knife Cutter is a next-generation digital cutting system engineered for the advertising and display industry, ideal for materials like KT board, POP displays, XPS foam, and corrugated cardboard.

With cold-cutting precision, it eliminates burn marks, rough edges, and die costs — delivering clean, accurate results every time.

Powered by IBON SmartOS, AI nesting, and CCD visual positioning, it ensures unmatched accuracy and efficiency. The hybrid cutting head design and industrial-grade structure enable 24/7 operation with low maintenance, helping factories save on labor and materials while meeting global green standards.

🌟 Core Advantages

AI SmartOS System – Self-developed intelligent control with AI nesting (15%+ material savings), 2,000+ cloud templates, and mobile remote monitoring.

Multi-Tool Flexibility – Vibrating knife, rotary cutter, and creasing wheel handle diverse advertising materials in one pass.

Industrial Durability – Aerospace-grade linear motors, dual Mitsubishi servo drives, and reinforced steel frame ensure precision and longevity.

Eco-Friendly Cutting – Zero smoke, 80% lower energy use than lasers, CE & UL certified for global environmental compliance.

Precision Engineering – Aviation-grade 45mm aluminum platform with ≤0.1mm flatness and 9KW multi-zone vacuum adsorption for strong material hold.

IBON — Cut Smarter. Work Cleaner. Produce Faster.

Empowering the advertising industry with precision, automation, and sustainability.

IBON CNC Carton Cutting Machine — Fast, Accurate, Smart, and Efficient

Fast

The IBON carton cutting machine operates 3–5 times faster than traditional manual cutting, reaching speeds up to 1200mm/s. It’s ideal for factories handling diverse orders and short lead times, ensuring rapid sample production and on-time delivery.Accurate

Powered by intelligent CNC control, every operation is digitally simulated to eliminate manual errors caused by fatigue or inexperience. This guarantees consistent precision, minimizes material waste, and ensures high-quality cutting results every time.Saving

Compatible with major CAD software, IBON cutters allow real-time pattern corrections during cutting, enabling quick sample development and design updates. This helps customers stay 2–3 days ahead of competitors in responding to market changes.Smart

Equipped with IBON SmartOS, the system offers adjustable cutting depth, flexible automatic nesting, and multi-tool switching for different materials. The machine combines high intelligence with easy operation, achieving faster setup and maximum efficiency.

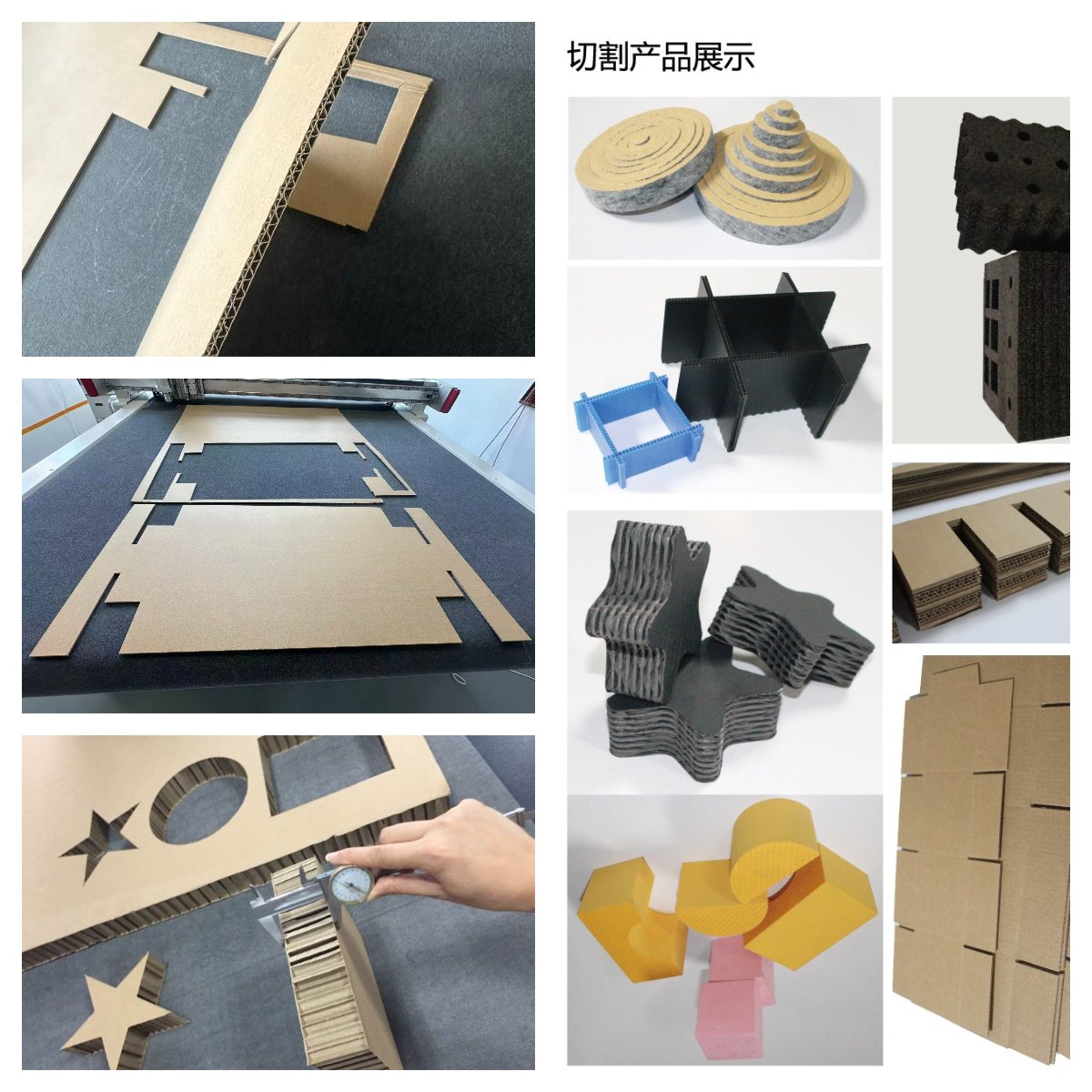

Other Cutting Materials

IBON CNC Cutting Machine Models & Configurations

Model Cutting Size (mm) Cutting Head & Arm Feeding System

IB1410 1400 × 1000 1 & 1 No

IB1813 1800 × 1300 1 & 1 No

IB1625 2500 × 1600 1 & 1 No

IB1625A 2500 × 1600 1 & 1 Yes

IB1630 3000 × 1600 1 & 1 No

All IBON models come with one standard cutting head equipped with multiple tools — including oscillating knife, creasing wheel, pen, and pinch roller — for versatile cutting, creasing, and marking of various materials.

An optional dual-head configuration is available to expand functionality with milling, V-cutting, and punching tools, providing higher efficiency for complex jobs.

Larger models, such as the IB1625A, can be fitted with an automatic feeding (conveyor) system to support continuous cutting and large-volume production.

Certificate

CE, ISO9001 certified,

Design patent certifications,

Utility model patent certifications,

Software copyright certifications.

TOP 10 Footware Machinery Enterprise,

TOP 10 Innovative Enterprise,

CTP(China Torch Plan) Key New High Technology Enterprise.

etc.

IBON CUTTING MACHINERY – FAQ

1. Are you a factory or trading company?

We are a professional CNC cutting machine manufacturer with over 10 years of experience, specializing in high-end digital leather cutters for flexible materials.

2. Can the machine be customized?

Yes. Our experienced design team can tailor solutions based on your material, size, and production needs to ensure the best cost-performance.

3. What’s the difference from laser cutting machines?

IBON knife cutters use oscillating blades—no laser, no smoke, no burn marks—ensuring smooth edges and a cleaner working environment.

4. What’s the warranty?

We provide a 24-month warranty. Core parts are free if quality issues occur. Lifetime technical support is included.

5. Do you offer service after the warranty?

Yes, IBON offers lifetime remote technical support and spare parts supply.

6. It’s my first time buying from China. Can you help?

Yes. We provide DDU door-to-door delivery and full setup guidance for new buyers.