Product Description

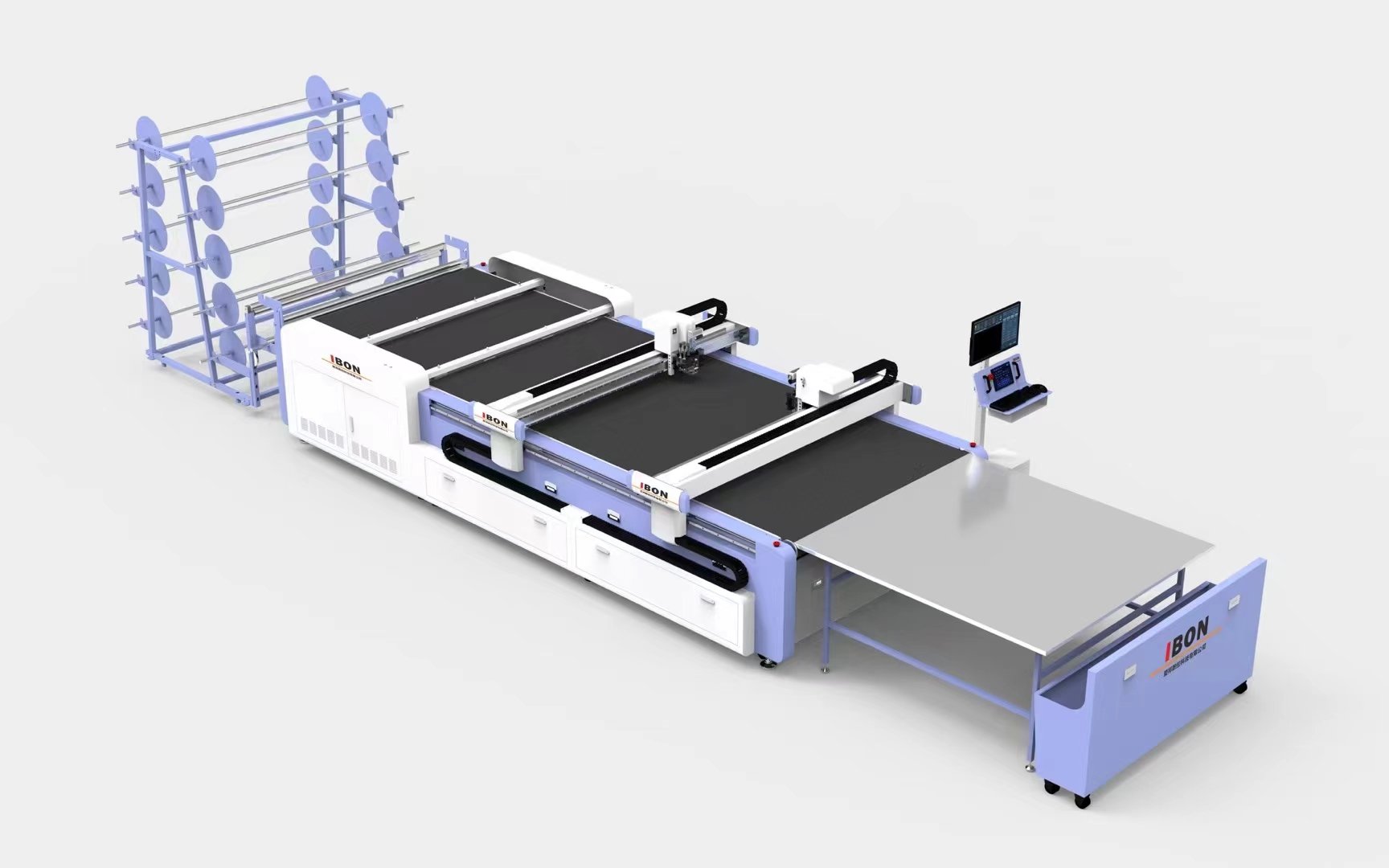

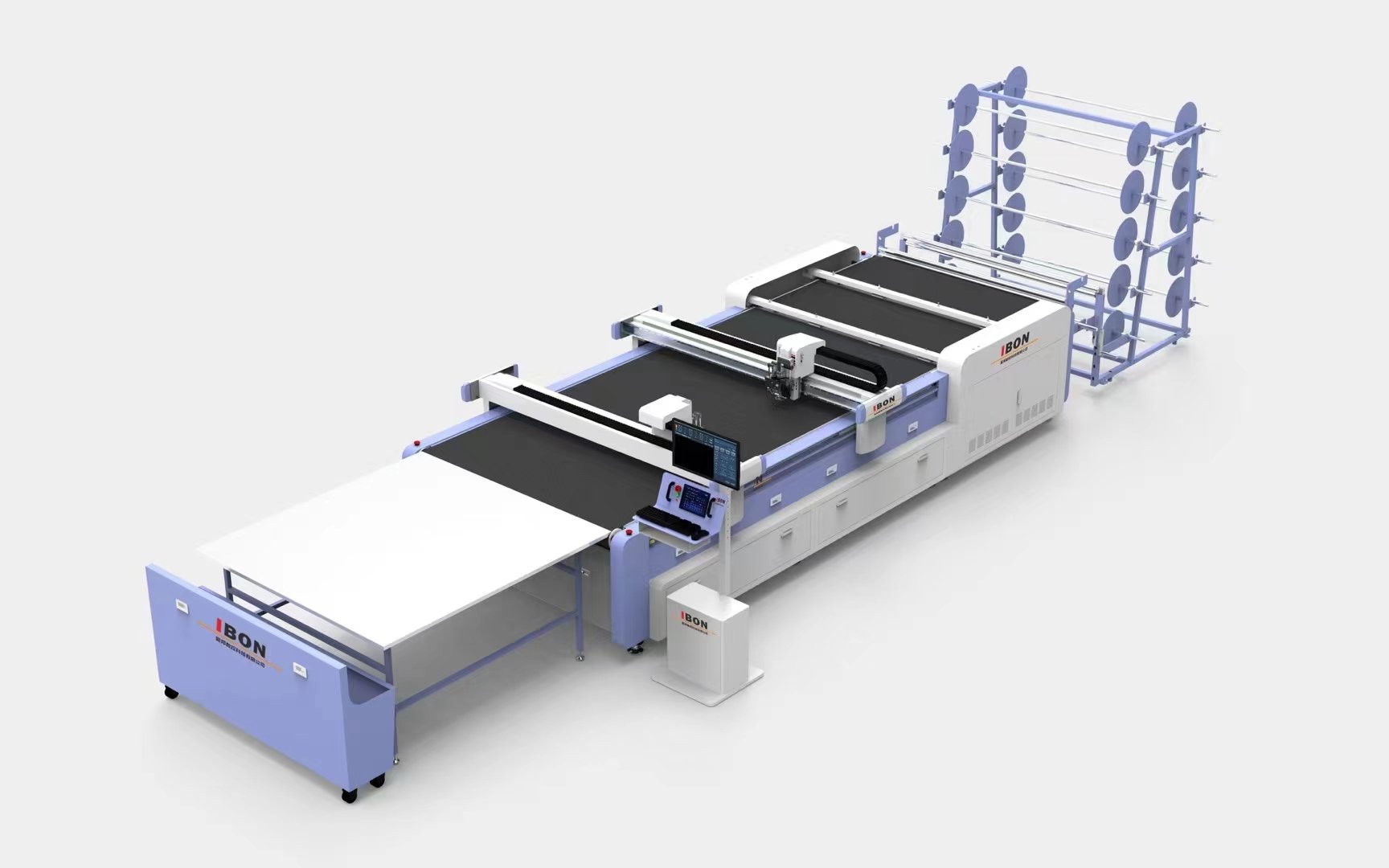

This High Efficiency Oscillating Blade Leather Cutting Machine is a professional cutting system for leather products.

It is of good quality, high speed, stable functions and competitive price, specially providing a revolutionary cutting solution for parcel,

footwear, garment, case and bag, car and plane chair, furniture and apparel industries.

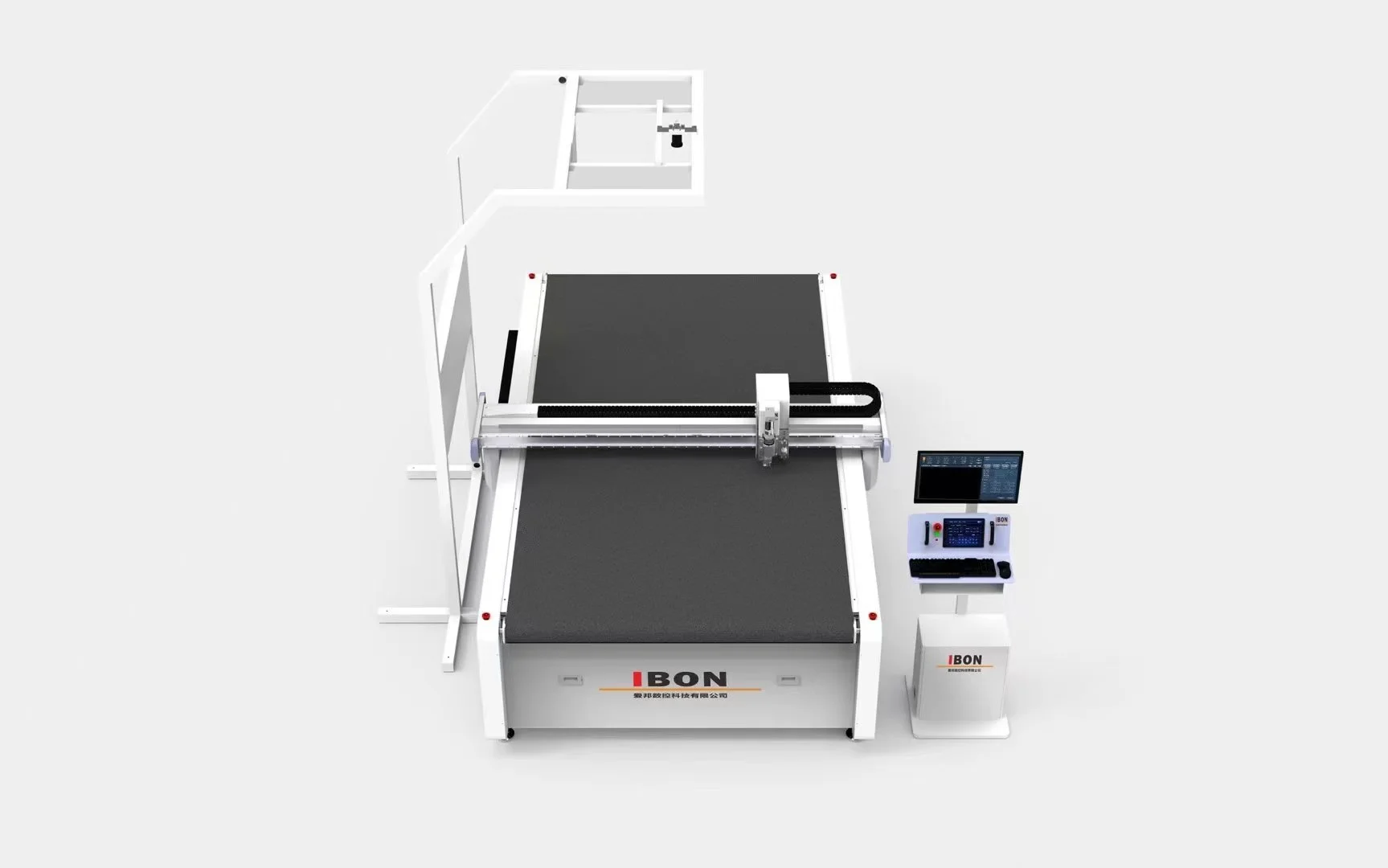

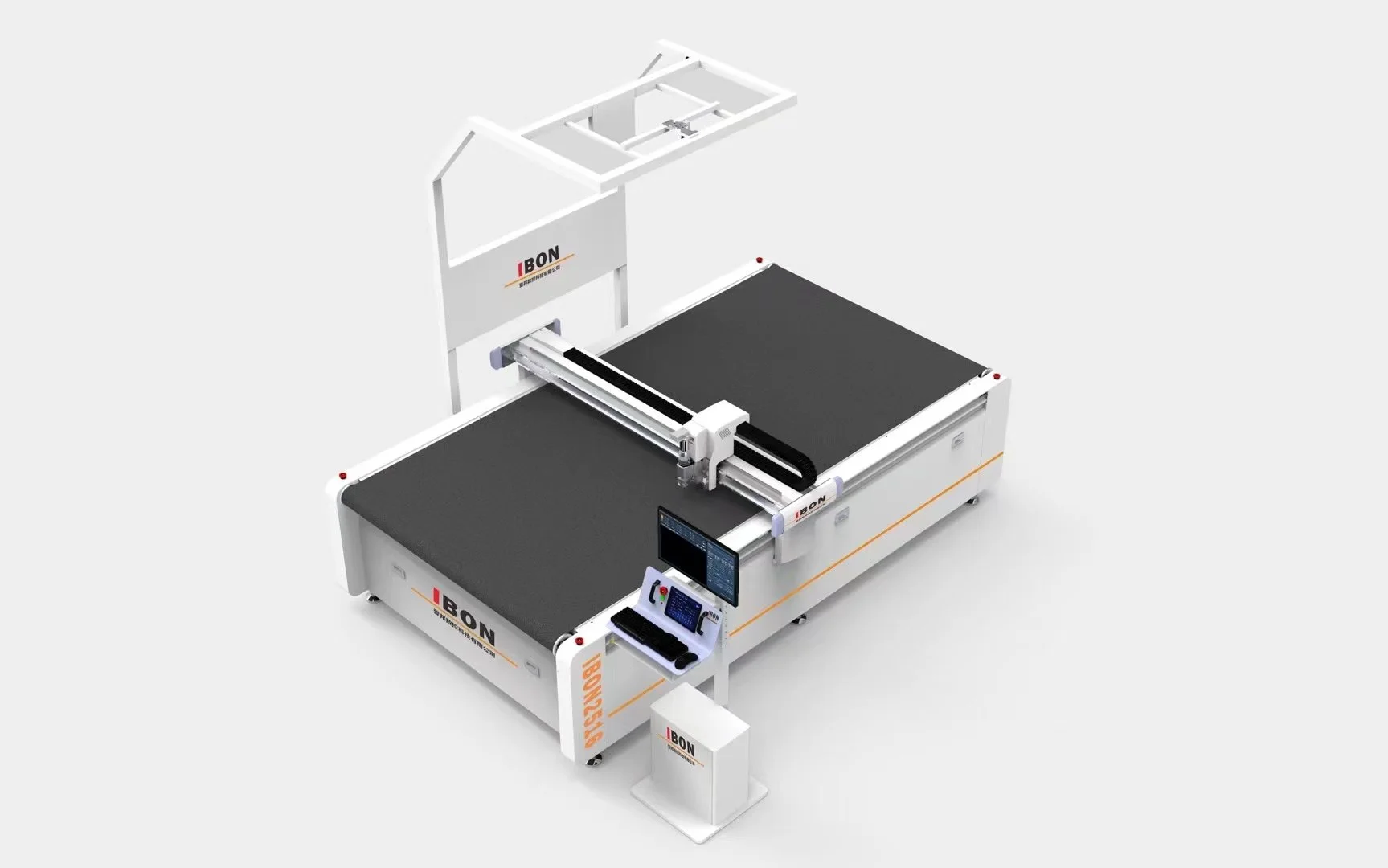

Technical Specifications — IBON IB1616 Flatbed Cutting Machine

Model IB1616 Effective Cutting Area 1600 × 1600 mm

Maximum Cutting Speed Up to 1200 mm/s (straight line)

Maximum Cutting Thickness ≤ 6 mm

Applicable Materials Genuine leather, synthetic leather, PVC leather, cardboard, carbon fiber, cowhide, sheepskin, pigskin, crocodile leather, and more flexible materials

Material Holding Method Vacuum absorption

Supported Machine Language HP-GL / GP-GL

Communication Interface Ethernet port

Cutting Accuracy ≤ 0.1 mm

Available Tools Oscillating knife, pen tool, hole punching tool

Oscillating Knife Electronically driven by Swiss high-frequency motor (18,000 rpm)

Cutting Functions Supports full-cut, kiss-cut, and dotted-line cutting modes

Vacuum Power 9 kW, 380V 50Hz / 220V 60Hz

Cutting Tools and Functions

Major Features of IB1616 Leather Cutting Machine

Dual-Head Smart Cutting System

Two cutting heads operate independently, completing cutting, punching, and marking in one seamless workflow — up to 3–6 times faster than traditional methods.High-Definition Projection

Real-time projection assists with defect detection and rapid nesting, ensuring precise material placement and minimal waste.Powerful Vacuum System

Multi-zone vacuum control allows flexible section activation, providing strong material stability during cutting.Intelligent Management System

Integrated software enables order tracking, nesting, and cutting reports for efficient production management.

Four Core Advantages

High Productivity – Dual-head operation dramatically boosts efficiency.

Labor Savings – Reduces 6–9 workers, saving up to RMB 270,000 per year.

Creative Value – Supports intricate, high-end pattern cutting for premium products.

Material Efficiency – Increases material utilization by 5–8%, lowering overall costs.

Packaging

Fairs

Certificate

CE, ISO9001 certified,

Design patent certifications,

Utility model patent certifications,

Software copyright certifications.

TOP 10 Footware Machinery Enterprise,

TOP 10 Innovative Enterprise,

CTP(China Torch Plan) Key New High Technology Enterprise.

etc.

IBON CNC Leather Cutter – FAQ

1. Are you a factory or trading company?

We are a professional CNC cutting machine manufacturer with over 10 years of experience, specializing in high-end digital leather cutters for flexible materials.

2. Can the machine be customized?

Yes. Our experienced design team can tailor solutions based on your material, size, and production needs to ensure the best cost-performance.

3. What’s the difference from laser cutting machines?

IBON knife cutters use oscillating blades—no laser, no smoke, no burn marks—ensuring smooth edges and a cleaner working environment.

4. What’s the warranty?

We provide a 24-month warranty. Core parts are free if quality issues occur. Lifetime technical support is included.

5. Do you offer service after the warranty?

Yes, IBON offers lifetime remote technical support and spare parts supply.

6. It’s my first time buying from China. Can you help?

Yes. We provide DDU door-to-door delivery and full setup guidance for new buyers.