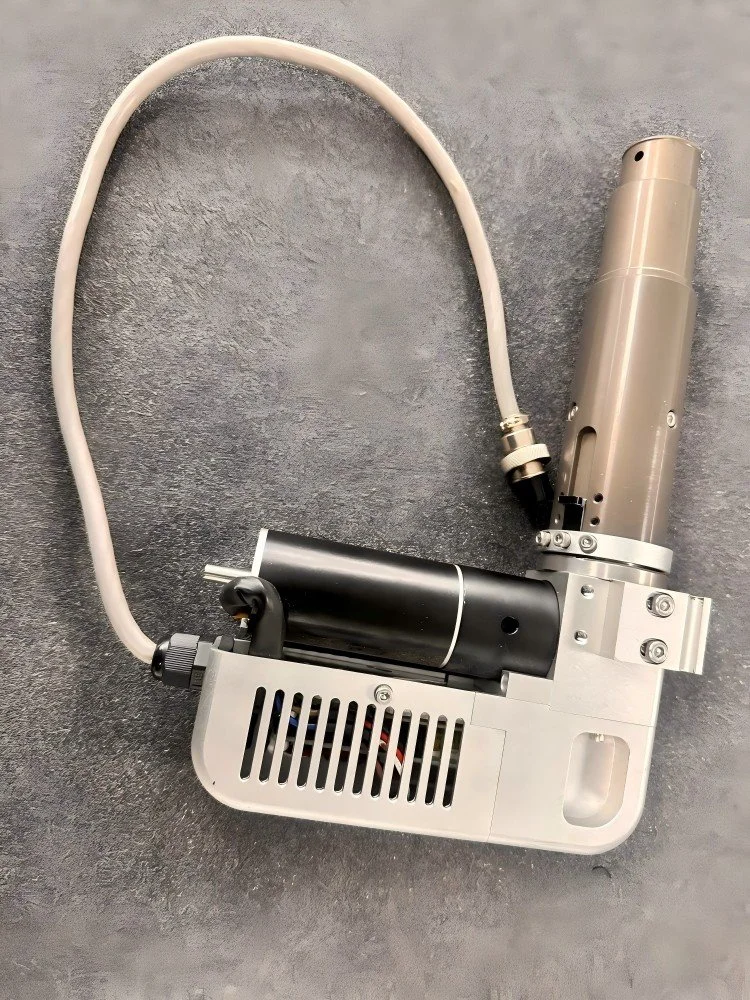

Pneumatic Oscillating Cutting Module

The Pneumatic Oscillating Cutting Module is a high-performance cutting head developed by IBON for processing thick, dense, or multi-layer flexible materials.

Driven by compressed air, this module provides powerful cutting force and stable performance, making it ideal for industries that require both depth and precision in cutting.

🔧 Compatible Machine Models

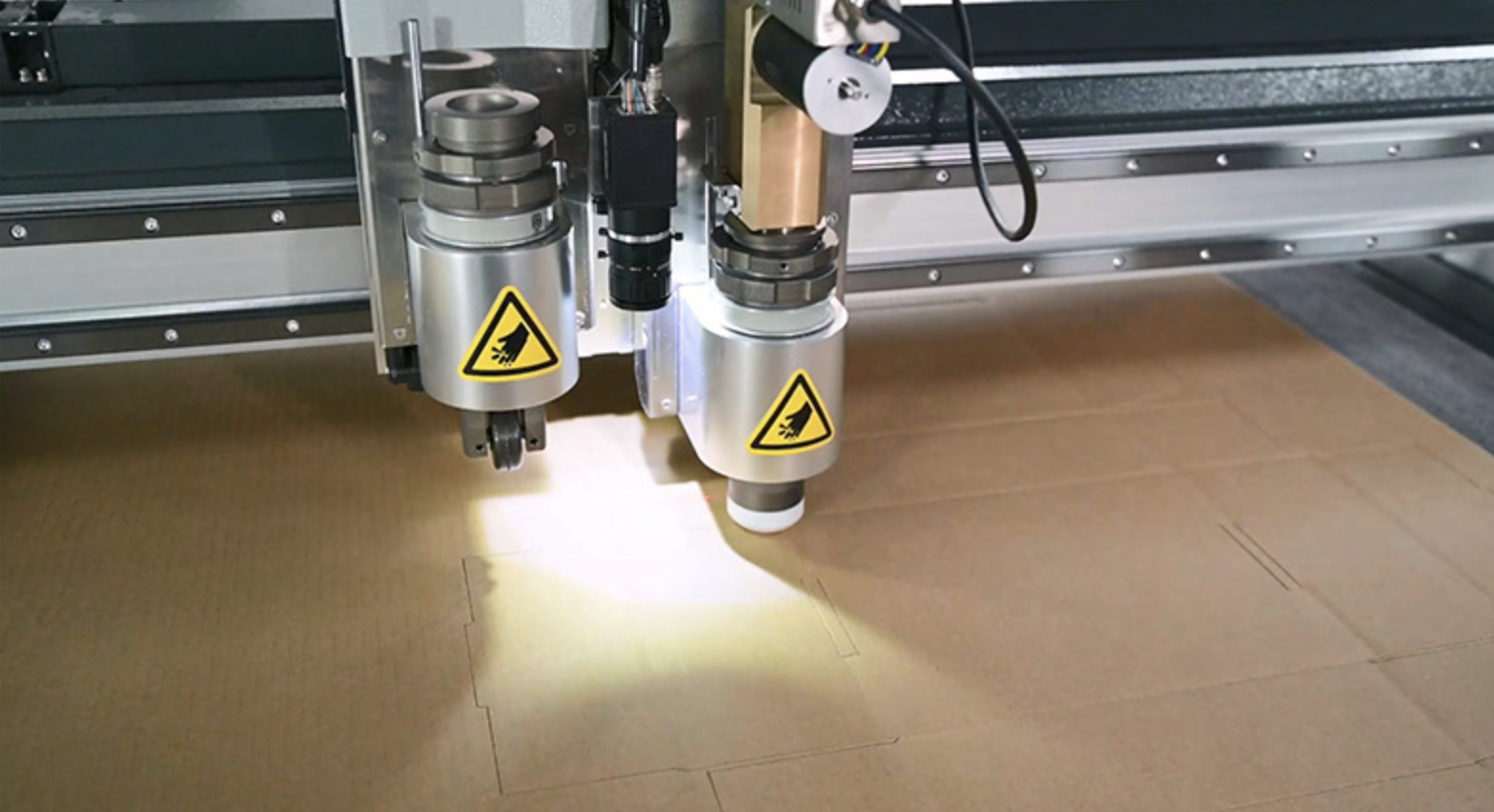

This module can be equipped on various IBON CNC cutting machines, including:

IB1616, IB1813, IB2516, and other large-format models

Dual-head or multi-tool configuration machines

Conveyor-type automatic feeding systems for continuous production

It integrates perfectly with IBON’s intelligent cutting system for industrial-grade production lines.

🏭 Applicable Industries

The Pneumatic Oscillating Cutting Module is widely used in:

Footwear industry – thick leather, outsole materials, EVA midsoles

Automotive interiors – carpet, insulation, composite materials

Packaging industry – corrugated board, honeycomb paperboard

Sports equipment – protective gear, mats, foam components

Furniture and upholstery – leather, sponge, cushion materials

Composite and technical materials – rubber, felt, carbon fiber

🪵 Compatible Materials

Multi-layer leather and synthetic leather

EVA foam / Rubber sheet / Sponge

Corrugated cardboard / Honeycomb board

Carpet / Felt / Soft plastic / PVC

Insulation and soundproof materials

⚙️ Main Features

Cutting thickness up to 18mm, ideal for thick or multi-layer materials

High-intensity pneumatic drive for strong and consistent cutting force

Multiple blade options for different materials and cutting depths

High precision for complex shapes and contours

Reliable performance backed by IBON’s 10+ years of automation experience

Stable operation & long service life, designed for heavy-duty industrial use